Spare parts supply for cleaning systems

Project motivation

What do you do if the high-pressure cleaner you urgently need has a clogged nozzle? The Kärcher logistics centre in southwest Germany ensures fast replacement of spare parts. The company relies on an intralogistics solution from TGW for this purpose. The Obersontheim facility sends all spare parts, accessories and some of the cleaning agents to its customers each year – this adds up to about 2.8 order lines a year.

"We looked for a systems integrator, covering as many aspects as possible. TGW offered all these features: They were able to implement the entire solution." Roland Fahrmeier, Vice President Logistics Management Kärcher

Key benefits

-

REDUCING LEAD TIMES to 30 minutes

-

SYNCHRONISING the different picking areas

-

STORAGE CAPACITY INCREASED by 40%

-

PICKING ERROR RATE REDUCED (from > 10% to < 0.01%)

Initial Situation

The rapid growth, continuous expansion of the range of articles and increasing direct supply to end customers made it necessary to devise a new concept for the location in 2009. To cope with the enormous quantity of shipments and the short delivery times required, the lead time of the orders in the distribution centre had to be reduced massively. In addition, the goal was to increase the storage capacity while cutting the error rate during order picking to under 0.01 percent.

Solution & Materialflow

- GOODS RECEIPT AND STORAGE

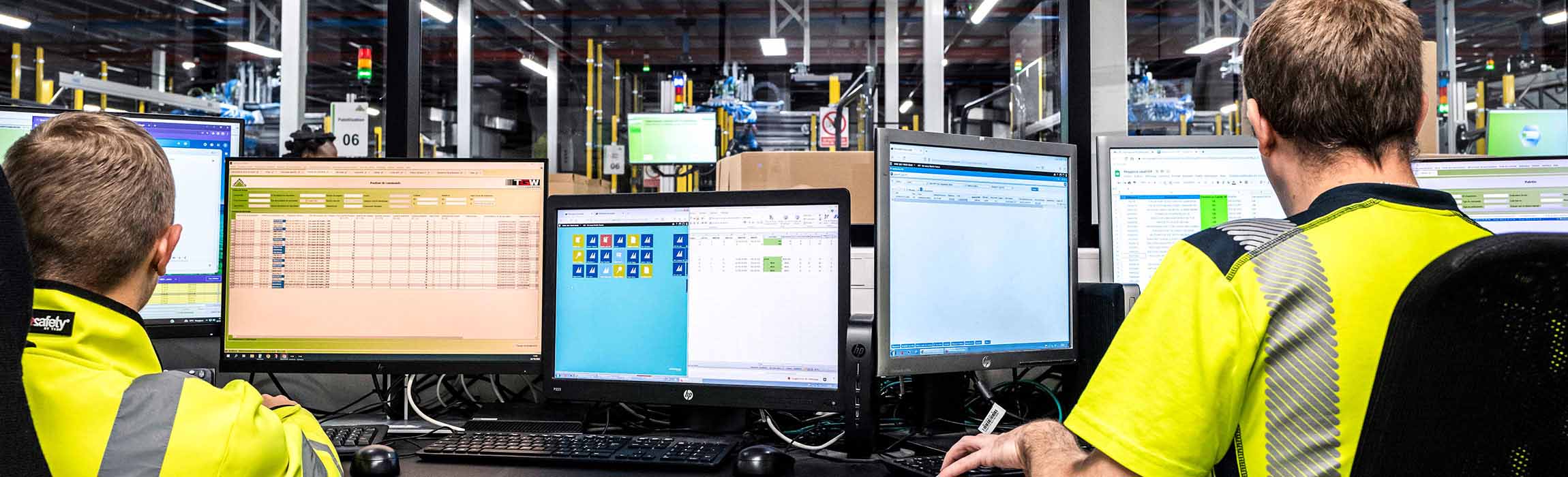

The automatic mini-load warehouse includes approximately 95,000 storage locations for totes. In eight shelving lanes that are each 77 metres long, our Mustang storage and retrieval machines ensure efficient storage and retrieval to/from the 14-metre-high shelves. The automatic mini-load warehouse supplies the order picking stations fully automatically. - PICKING

The picking system for Kärcher uses eight PickCenter goods-to-person workstations. Picking at the workstation is done by having two alternating source containers. Parallel to the small parts area, larger goods are picked in a separate area of the distribution center. A shuttle system is used as an intermediate buffer to enable consolidation of the orders. This reduces the number of individual packages that are sent to the customers, thus reducing shipping costs. - PACKING & OUTBOUND AREA

In addition to the goods in totes that automatically come from the shuttle system to the processing workstation, larger goods are provided manually. Most of the work in this area takes place in the afternoon between noon and six in the evening so that the orders are ready for shipment in time for the departure of the lorries.

Highlights

Picking efficiency

Higher order throughput is achieved through a reduction in the amount of time order picking employees spend walking. The automated systems allow shorter order processing times and allow customer orders to be fulfilled optimally via the different channels (dealers, private customers, service installers and shipment to international warehouses).

Kärcher also benefits from synchronisation of different order picking areas, increased warehouse capacity, reduced transport costs due to optimised packaging, and simultaneous reduction of the error rate.

About Kärcher

Kärcher is considered one of the world's leading providers of cleaning systems. The line of appliances, accessories and consumables is used both in private homes and commercial settings. From the logistics centre in Obersontheim, the company supplies customers on all continents with over 60,000 different spare and accessory parts.

CURIOUS?

Erich Schlenkrich

Vice President Business Development Industrial & Consumer

Message