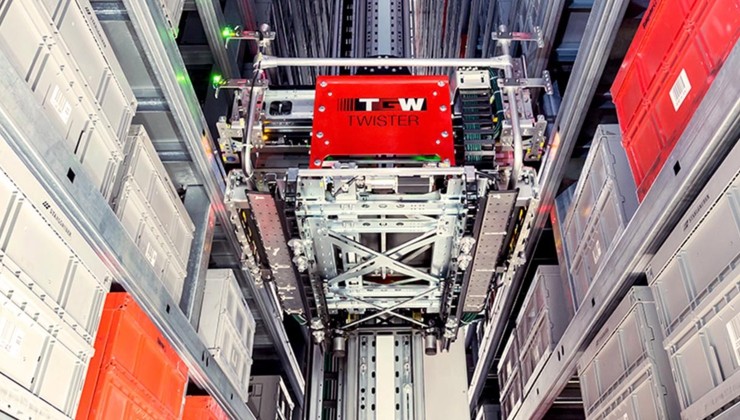

SUSTAINABLE, SMART SHUTTLE SYSTEM FOR TOTES, CARTONS AND TRAYS

PIONEERING

SUSTAINABLE

POWERFUL

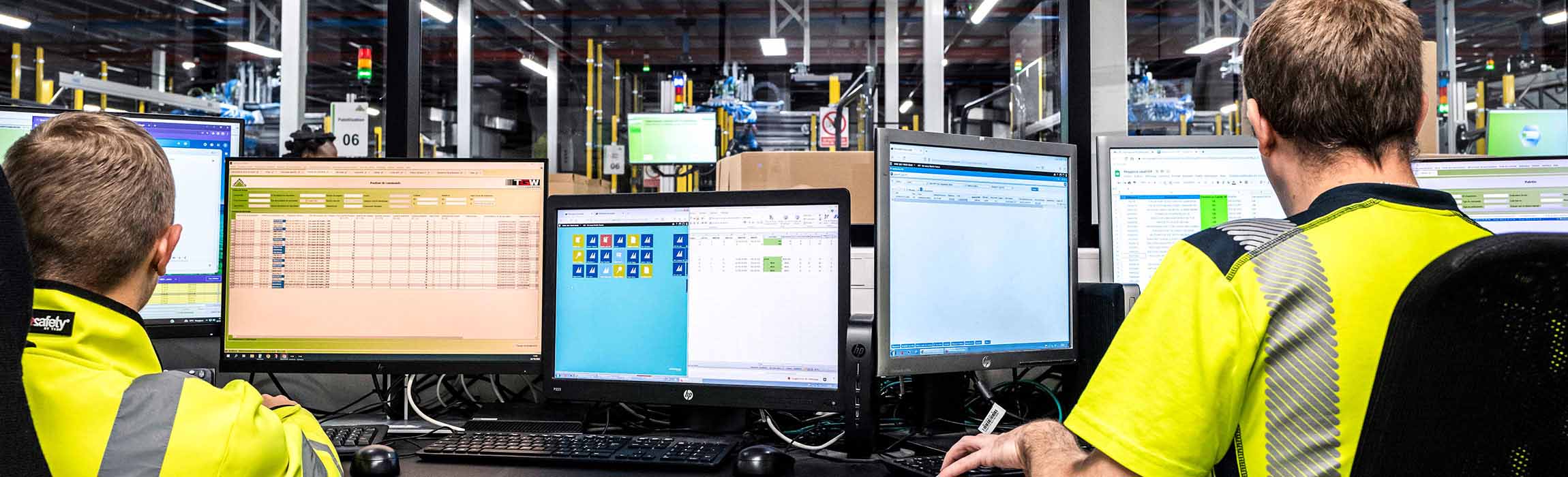

With the new generation of Stingrays, TGW is taking shuttle systems to a whole new level. The Stingrays are a component of the smart FlashPick® order fulfilment system and are self-healing thanks to their intelligent software and mechatronics. This means, for example, that load carriers will be automatically realigned if they are not optimally positioned in the shuttle rack. System operators enjoy up to 90 percent less manual intervention compared to other solutions.

Sustainability is another area where this new generation shines: since the covers are made of wood instead of plastic, 25 tonnes of plastic can be saved every year. TGW also brings multi-level energy management to the table (Smart Energy Strategy).

The new system also scores points for maximum performance: more than 24,000 Stingray shuttles have already been sold worldwide and they are the fastest on the market. They achieve a 25 percent increase in dynamics, improving the overall performance of the system by ten percent. The Stingrays can transport up to 1,500 load carriers per hour in each aisle.

GOOD

TO

KNOW

REMEDIES PROBLEMS AND ERRORS INDEPENDENTLY

Significant REDUCTION OF CARBON FOOTPRINT

MOST POWERFUL SHUTTLE SYSTEM IN THE WORLD

NO COMMISSIONING necessary (plug & play)

USE EVEN UNDER EXTREME CONDITIONS such as freezer temperatures down to -30°C

MAXIMUM AVAILABILITY AND SYSTEM LIFESPAN

PREDICTIVE MAINTENANCE

PIONEERING

THE WORLD'S LEADING SHUTTLE SYSTEM

- Self-healing – shuttles remedy problems and errors independently

- Foremost in freezer logistics – deep freeze automation for over 30 years

- Plug & play – no commissioning necessary

- Condition monitoring & predictive maintenance thanks to full data transparency

- 90% less manual intervention & maximum lifespan compared to other shuttle systems. This also reduces the amount of (maintenance) personnel required

- Optimal availability thanks to redundant system design

- Cloud-based updates for network security & upgrades

- 24,000 Stingray shuttles sold

SUSTAINABLE

EFFICIENT USE OF RESOURCES

- Green logistics – significant reduction of carbon footprint

- Innovative, regionally-sourced wooden cover saves 25 tonnes of plastic

- Smart Energy Strategy – functions such as smart kinematics, energy-saving mode, Super Caps etc. make the Stingray shuttle highly energy-efficientDesigned for maximum energy recuperation

- Designed for maximum energy recuperation

- Low total cost of ownership – economic advantages, especially during periods of high energy and raw material prices

- Long product lifespan and 75% less maintenance effort

- Minimised investment and process costs thanks to direct handling of load carriers

- Less sealing of the soil surface thanks to clad rack construction

POWERFUL

Driving your business

- Most powerful shuttle system in the world

- 10% higher performance with the new system – 1,500 load carriers per hour in each aisle

- Solution tailored to customer needs – flexible implementation of standardised system components

- Higher storage density and flexibility due to varied load carrier types (cartons/totes/trays) and sizes

- Lowest cost per storage location at a high performance level

- Flexible, scalable warehouse throughput due to the number of shuttles being adaptable at any time

INTERESTED?

The following topics like shuttle-systems and mini-load systems might be interesting for you as well – Learn more about our services and if you have any questions, contact us!