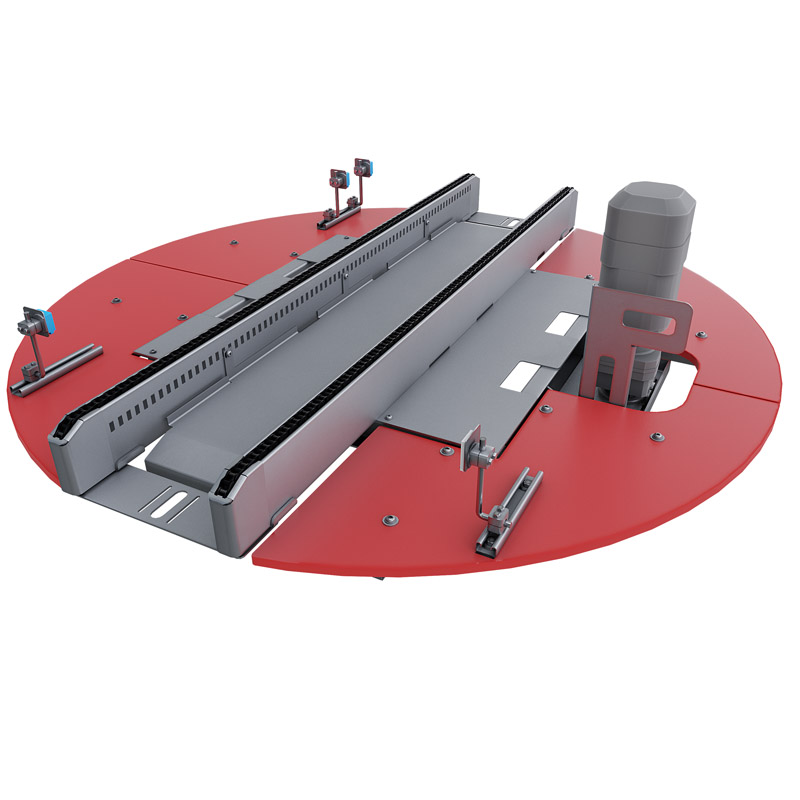

Conveyor Systems for Roll Cages

Improved Material Handling Starts With Better Roll Cage Handling Systems

Roll cages are the backbone of grocery market delivery cycles, and we’ve spent over 30 years perfecting the conveyor systems that move them. From frozen zones at -30 °C to ambient environments reaching 40 °C, our technology is built to perform with unwavering precision and efficiency. See what’s possible for your business.

TGW Logistics’ conveyor systems are compatible with various material handling environments, including mixed transport of roll cages and pallets up to 1.000 kg. Our systems adapt to your container type, so both metal and plastic-based roll containers get consistent, stable transport every step of the way.

Explore our full range of intelligent container handling systems, including:

Key Benefits of TGW Logistics’ Conveyor Systems

When moving hundreds (or even thousands) of roll containers a day, the equipment you rely on needs to keep pace.

That means performing with precision, adapting to your space, and holding up over time. These are the design principles behind every TGW Logistics’ roll cage conveyor, and the benefits are far-reaching.

- Reliable performance across all temperature zones

Engineered to operate in environments ranging from -30 °C to +40 °C without compromising performance. - 30+ years of expertise built into every solution

Proven technology backed by decades of fulfillment, insight and innovation. - User-friendly operation

Simple to use, no special skills required—keeping onboarding and daily processes seamless. - Tailored to your needs

Customer-specific conveyor equipment is designed for the exact dimensions of your roll containers. - Flexible material handling

Capable of transporting roll cages and pallets in mixed loads with a combined weight of up to 1.000 kg. - Built for durability

Robust construction and low-maintenance design ensure operational reliability for up to 20 years. - Compatible with different container bases

Supports both metal and plastic base roll cages.

Technology’s Role In Material Handling

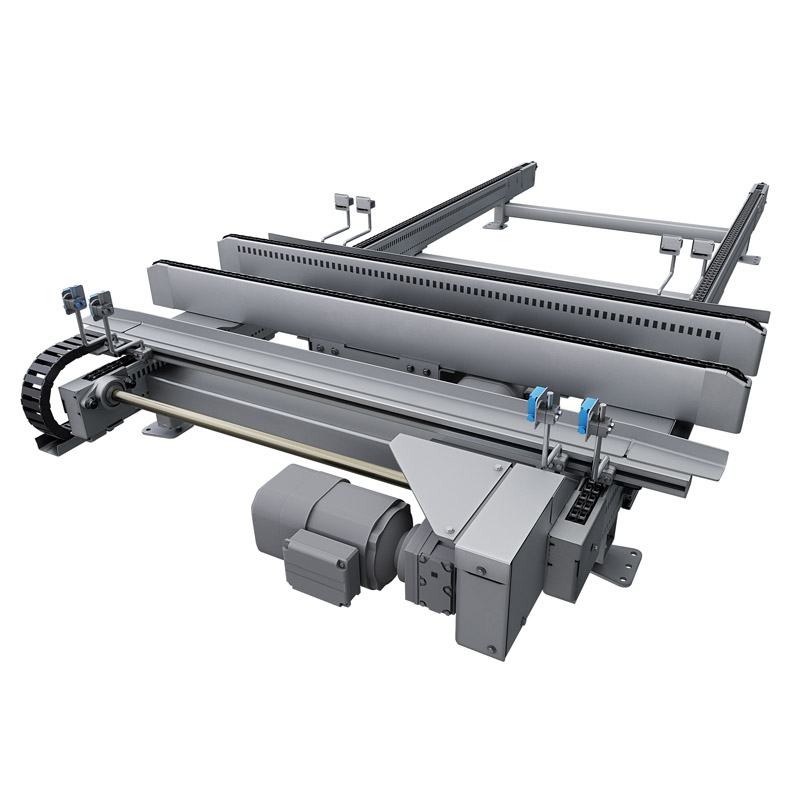

The strength of a TGW Logistics’ conveyor system shines through in the details that keep it running daily. Thoughtful design features like precision hand wheel chain tensioning, overlapping chain tracks, and low-friction guide wedges work quietly in the background to minimize wear, improve safety, and facilitate uninterrupted transport. Even in environments with incline changes or extreme temperatures, our systems are engineered for reliability where it matters most—on the ground, in motion, and at scale.

Learn More About Our Conveyor Products

Ready for a modular conveyor system that adapts to your workflow?

When your operation needs to scale, speed up, or shift direction, TGW Logistics makes it possible.

TGW Logistics est une entreprise appartenant à une fondation dont le siège se trouve en Autriche et qui est un leader mondial de l'automatisation des entrepôts et de la logistique d'entreposage. En tant qu'intégrateur de systèmes reconnu, fort de plus de 50 ans d'expérience, nous fournissons des services de bout en bout clé en main : conception, fabrication, installation et maintenance de centres de préparation des commandes alimentés par la mécatronique, la robotique et des solutions logicielles avancées. Avec plus de 4 500 employés répartis entre l'Europe, l'Asie et l'Amérique du Nord, nous combinons l'expertise, l'innovation et un dévouement focalisé sur le client pour aider votre entreprise à se développer. Avec TGW Logistics, vous avez la possibilité de transformer la logistique de votre entrepôt en un avantage concurrentiel.