![[Translate to North America:] warehouse management system](/fileadmin/_processed_/f/d/csm_Orchestrating_Goods_Flow__Header_f3ea0360ee.png)

![[Translate to North America:] warehouse management system](/fileadmin/_processed_/f/d/csm_Orchestrating_Goods_Flow__Header_f3ea0360ee.png)

Orchestrating Goods Flow: How Integrated Warehouse Management Systems Synchronize Picking, Packing, and Shipping

Simply introducing automated elements into your warehouse doesn’t guarantee improved efficiency. In fact, when the right hand doesn’t know what the left is doing or when the handoff from stage to stage of material flow isn’t organized, chaos, bottlenecks, and increased costs can be the result. However, when equipment and software are working harmoniously together, and goods seamlessly move through the process, a facility functions like a world-class orchestra. Each element performs as it should and is designed to collaborate flawlessly with the others, from storage and picking to packing and shipping.

In other words, the orchestration of goods flow matters immensely because synchronized operations increase accuracy and speed up throughput. But who conducts this orchestra? Integrating warehouse management system (WMS) software gives you the tools and control to keep goods flowing fluidly from the first touch point to the last.

Challenges Without Integrated Systems

Even if picking, packing, and shipping processes are automated, relying on warehouse control systems software (WCS) that each directs a separate piece of automation introduces the opportunity for slowdowns and accuracy errors. These handoffs from system to system are where mistakes can occur and information can be lost. Meanwhile, the industries of e-commerce and consumer goods thrive on fast shipping times and meeting consumer expectations for delivery. And the handoff at every stage of a warehouse that’s not fully integrated with WES and WMS isn’t compatible with the speed and accuracy required.

Non-orchestrated handoffs can slow the overall material flow and lead to bottlenecks where the next processing step is not ready to efficiently handle the goods and orders being handed off. These bottlenecks can impact the efficiency of the entire warehouse, slowing order fulfillment.

![[Translate to North America:] warehouse management system conveyor systems](/fileadmin/_processed_/2/1/csm_Orchestrating_Goods_Flow__Inner_1_b92a300a19.png)

![[Translate to North America:] warehouse management system conveyor systems](/fileadmin/_processed_/2/1/csm_Orchestrating_Goods_Flow__Inner_1_b92a300a19.png)

Key Components of an Integrated Warehouse Management System

Integrated software is the central nervous system that directs all of the elements of your warehouse. Your warehouse management system manages each step of the process, overseeing material flow, optimizing storage, tracking inventory, and even analyzing data. Your warehouse execution system (WES) executes all operations and dynamically tracks the flow of goods in real time. Think of integrated software as your central command for data and workflows, keeping processes running smoothly and helping managers identify areas for improvement. Let’s look at how integration functions in each step of the process.

As goods are received by the warehouse, accurate inventory tracking and highly organized material flow set the pace for the rest of the process. TGW Logistics offers conveyors, decanting stations, and scanning technology that all communicate with your warehouse software to acknowledge the goods as received.

The next step is to store this product appropriately and efficiently. TGW Logistics’ automated storage and retrieval systems (ASRS) are directed by your warehouse management software to transport each load to the right storage location, logging the movement and keeping inventory updated.

Goods-to-person solutions simplify and speed up the picking process by delivering load carriers directly to ergonomically designed picking stations for workers to select the goods in each order. WES and WMS manage this phase of the flow as well, sending goods to specific workstations based on availability, to eliminate backups and bottlenecks.

Additionally, TGW Logistics’ modular and customizable unit load conveyor systems allow for deft movement of any type of pallet, including large and/or bulky items with non-standard dimensions. Components include turntables, which enable easy reversing and changing direction of pallets, and pallet lifts, which move vertically to shift pallets into storage spaces of any height. Automated palletizing equipment efficiently packs and unpacks pallets in order as dictated by the integrated software, and also removes broken or otherwise unsuitable empty pallets from circulation.

Different orders have different packaging needs, and automation allows for segmentation without requiring human intervention. WMS and WES determine each order’s packaging needs and deliver them to the appropriate spot, whether that be a boxing machine, a poly bag machine, or manual stations.

Finally, when orders are safely packed and ready to be distributed, automated conveyors guide each one to the right dock door based on transportation method and destination. Alternatively, having knowledge of pickup schedules and the current backlog, your warehouse software may send orders to a buffer area to be held until they need to be on the dock to be loaded.

How Integration Improves Industry-Specific Operations

According to MIT researchers, the “warehouse of the future” is “a highly automated, interconnected system that leverages automation and digitalization.” And Interact Analysis reports that 26% of all warehouses will have some form of automation by 2027.

While any type of warehouse with fully integrated automation solutions will see an increase in efficiency, designing a synergistic system will have specific impacts on select industries. In the realm of retail and consumer goods logistics, expect faster order cycles and fewer errors, resulting in fewer returns and costly reshipments. In the grocery and cold chain logistics world, temperature control and food safety are obviously of the utmost importance. Carefully orchestrating the flow of goods in these types of facilities enables smooth handling and less damage and spoilage of perishable goods. Meanwhile, integrating automation in industrial logistics allows for more precise management of a wide variety of mixed SKUs, as well as the proper handling of bulk inventory and heavy items.

![[Translate to North America:] warehouse management system](/fileadmin/_processed_/d/a/csm_Orchestrating_Goods_Flow_Inner_2_912014d916.png)

![[Translate to North America:] warehouse management system](/fileadmin/_processed_/d/a/csm_Orchestrating_Goods_Flow_Inner_2_912014d916.png)

TGW Logistics’ Integrated Approach

TGW Logistics is an industry leader in designing customized, modular, and scalable warehouse automation solutions, combining software, hardware, and maintenance support to keep your facility moving. Our big-picture approach considers not only what equipment and software best suit your business needs but also how these elements will work together as a single ecosystem to produce the best possible outcome.

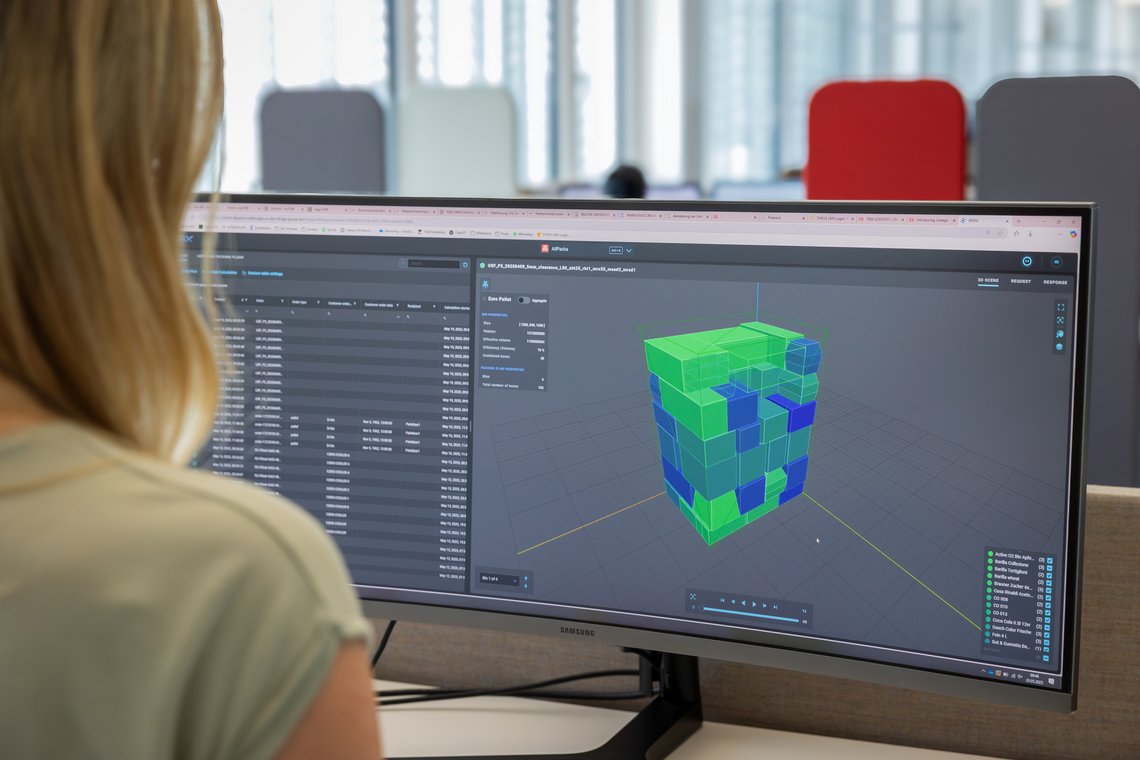

Every warehouse manager knows that automation isn’t simply a method of moving goods around a space. TGW Logistics is pioneering advancements in smart supply chains, using AI technology, internet-enabled warehouse management system software, and advanced robotics to fully inform and optimize warehouse logistics in real time. We’ll work with you to identify your ideal tech stack, ensuring that each level communicates seamlessly with the others, creating a singular, fluid workflow that constantly assesses and improves itself.

Moving Beyond Envisioning an Integrated Facility

By now, we’ve established that investing in intralogistics and fully orchestrating goods flow from storage through shipping will result in increased efficiency that will certainly be felt on the bottom line. Integrating automation elements also produces less waste, maximizing energy efficiency and improving inventory management. While such an upgrade may seem daunting, we’ve seen the incredible ROI that clients have experienced after fully integrating software, equipment, and support services throughout their facilities. Partnering with TGW Logistics to plan and execute a fully integrated warehouse management system will pay for itself through reduced labor costs, increased productivity, and fewer errors.

Ready to synchronize your picking, packing, and shipping? Contact TGW Logistics to explore integrated warehouse solutions.

![[Translate to North America:] warehouse management software](/fileadmin/_processed_/3/d/csm_Next_Gen_WMS_Header_7db70bb625.png)

![[Translate to North America:] warehouse management system](/fileadmin/_processed_/8/a/csm_WMS_SoftwarePillar_Header__23d53a3ea4.png)