- the shuttle-system uses the shelf as the main supporting element

- A challenging realization phase

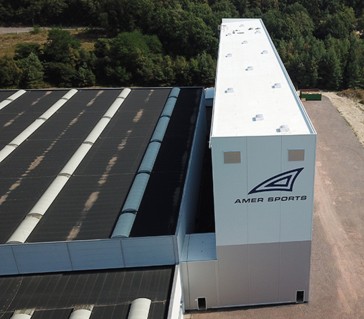

In Überherrn, Germany, the first shuttle silo is being built for Amer Sports. In doing so, TGW is expanding its steel construction product-range by adding another innovative product.

In addition to classic in-house shuttle systems, TGW now also offers so-called silo warehouse solutions, meaning that the shelf itself is the supporting structure for the roof and wall elements of the building’s shell, which can provide a considerable reduction in construction costs.

Amer Sports is a Finnish sporting goods company. Founded in 1950, the company is based in Helsinki and bundles well-known brands such as Wilson, Atomic, and Salomon. As part of upgrading the company’s central warehouse in Überherrn, a German city near the French-Luxembourg border, TGW’s Finnish customer opted for an automatic tote warehouse outfitted with the energy-efficient Stingray shuttle system.

A technically sophisticated solution

In its silo version, the shuttle-system uses the shelf as the main supporting element. At a length of 96 meters and a width of 13 meters, the system provides 80,000 storage slots in three lanes. The system’s compact design is a decisive argument in favor of this solution. At a height of up to 27 meters, optimum floor-space utilization is ensured. Up until now, this product’s version had only been available for pallet systems but not for tote or carton shuttles.

In order to realize a technically sophisticated solution such as this, the construction needed to be adapted to the kinetic energy of the shuttles that move along the aisles. Strong forces occur when the shuttles accelerate and decelerate, so the metal structure of the shelving needs to be able to reliably absorb these forces.

“We have been noticing that total cost of ownership is becoming increasingly more important to customers. This is why TGW not only looks at initial investments, but also considers ongoing operating costs over the entire lifetime of a business, not only for our tried and tested mechanical components as well as our software and our control and robotics systems – but also in steel construction”, says Markus Augeneder, CEO Central Europe at TGW Systems Integration.

A challenging realization phase

Wind and snow loads must be absorbed by the shuttle racks. The decisive factor here, more than anything else, is the joining of walls and the ceiling construction to the shelf as well as to the base plates. Markus Augeneder describes the challenge like this: “Assembly work at a height of 30 meters as well as local weather brings about some interesting conditions. Still, for Amer Sports, we were able to meet all the technical goals and are also keeping to a really ambitious project time-plan.”

Technical tolerances for the automatic shuttle warehouse are extremely tight because safe and failure-free operation must be a given at all times. “This is why the buildings and all technical parameters are monitored during ramp-up and operation, so we can generate the relevant data from that”, Markus Augeneder says.