Automating the Middle Mile: How Intralogistics Bridges Storage and Fulfillment

A crucial step in the material handling process lies between inbound and outbound logistics. It’s called the middle mile, and it involves moving goods from large storage warehouses to fulfillment hubs. You may not hear about it much, but it’s a highly complex and important step in your intralogistics operation.

Companies that rely on large-scale product distribution receive goods in from their manufacturers or suppliers at storage facilities. These warehouses are often in coastal areas or near ports to facilitate the arrival of inbound shipments from overseas. From there, goods are either stored or sorted and shipped to the company’s regional fulfillment hubs, located closer to customers. After arriving at fulfillment centers, goods are stored to await shipping or filtered directly into the center’s outbound process.

This sounds straightforward, but a successful middle-mile process requires strategic planning backed by automated warehouse solutions that support a healthy intralogistics system. Only then can you bridge storage and order fulfillment.

Why Automating the Middle Mile Matters

Consumer expectations have significantly changed over the last decade, particularly in the retail and consumer goods sectors. The convenience of an omni channel buying experience, faster delivery times, and product variety have raised the bar on service levels. To retain customers, you must keep pace with the shifting consumer landscape.

In addition to rigorous consumer demands, the ongoing labor shortage significantly strains intralogistics operations. Overreliance on manual labor results in slower throughput and an uptick in material handling errors.

You can meet these challenges head-on with automated warehouse solutions that drive middle-mile success. Technologies such as automated storage systems, conveyor networks, and palletizers support fast and efficient throughput so goods can be transported from warehouses to regional fulfillment centers without delays.

Warehouse automation also helps fill the gap created by the labor shortage. Instead of relying on manual labor, you can upskill employees to work alongside automated systems. Striking a balance between skilled labor and automated solutions results in a cost-effective and highly efficient middle mile.

Core Components of Middle-Mile Automation

The middle mile can encompass a large chunk of the supply chain, so it needs to operate as smoothly as possible. Storage and transport are the primary functions of the middle mile, requiring specific automated warehouse intralogistics systems.

Product volume alone is a significant obstacle in consumer goods and retail logistics. It’s imperative that goods arriving at your storage facility get inputted into the inventory and stored based on product demand and fulfillment center destination.

An ASRS enables precise inventory management by scanning goods into the system as they arrive. Items are then placed in a high-density storage system based on SKUs. These vertical storage units allow optimal space utilization so that you can handle larger volumes without expanding the footprint.

Shuttle systems speed the order retrieval process while reducing the need for manual labor. An ASRS supports fast, accurate order retrieval and sorts products based on destination and delivery route.

Maintaining a constant flow of goods is crucial throughout the middle mile. Automated conveyor systems and AMRs are two of the most effective warehouse solutions for continuous throughput at your storage facility.

After products are retrieved from an ASRS, they’re transported to an automated conveyor system that can handle large volumes with high speed and accuracy. The system automatically routes items based on destination and transports them to the correct station for shipping.

AMRs can support throughput continuity by moving large or awkward packages that the conveyor system can’t handle. They prevent bottlenecks and enable you to scale throughput during peak seasons or pull back when demand slows. AI-powered robotics further enhance AMR capabilities, enabling more sophisticated navigation, decision-making, and task execution within the warehouse.

Middle-mile logistics requires managing bulk shipments at inbound and outbound. Automated palletizing and depalletizing systems are invaluable at this stage. They eliminate the need for strenuous labor and support fast, organized loading and unloading.

Palletizers use data to configure pallets and optimize shipments. They leverage metrics such as product dimension, weight, and final destination to create stable pallets that maximize truck space. Palletizers create mixed pallets in facilities that handle a wide product variety, ensuring all items make it to the correct destination.

How Software Powers Warehouse Intralogistics

The automated warehouse solutions that support the middle mile need a reliable logistics tech stack to operate smoothly. This includes a Warehouse Management System (WMS), which syncs all automated equipment and monitors every step included in warehouse intralogistics.

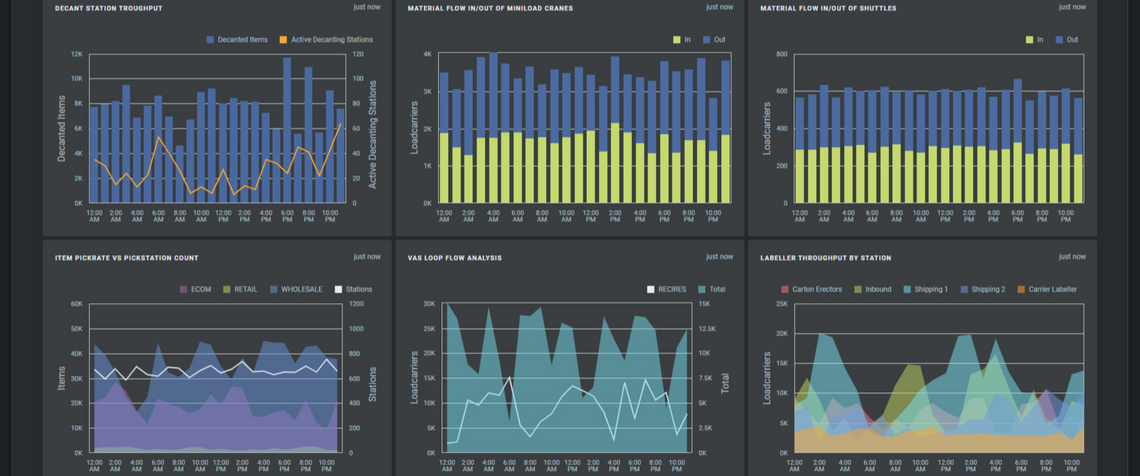

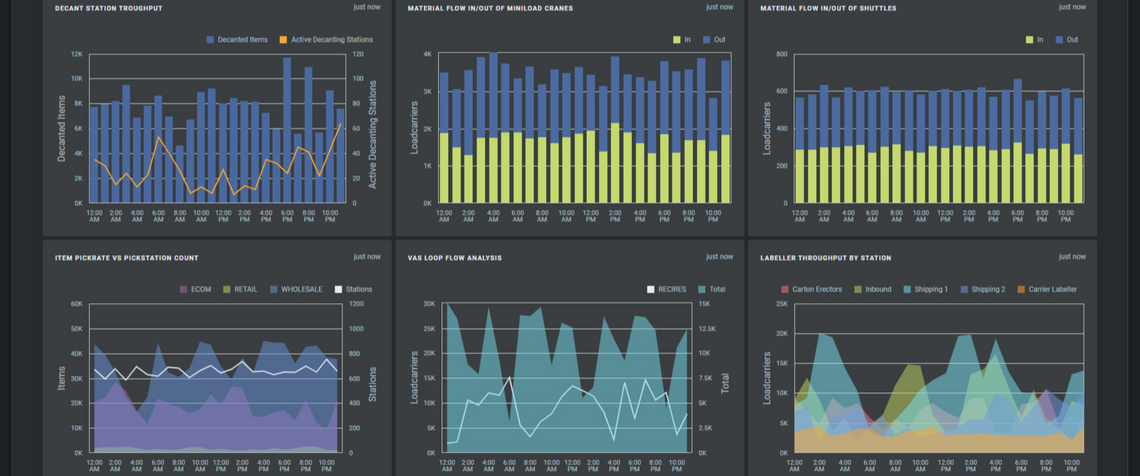

A key component of a WMS is a Warehouse Execution System (WES). This software manages daily tasks and brings high precision to a facility’s workflow. It conducts real-time coordination between incoming shipments, storage requirements, and outbound priorities. A WES also supports the unified operation of the ASRS, conveyor networks, AMRs, and palletizers. The result is a continuous middle-mile workflow without bottlenecks or unnecessary downtime.

Modern Warehouse Management Systems employ predictive analytics, enabling you to make informed decisions concerning middle-mile enhancements. Demand forecasting, labor optimization, and carrier scheduling reduce middle-mile costs and support an efficient outbound operation to ensure regional fulfillment centers always have the needed products.

Middle Mile Automation in Action

Automated warehouse solutions are necessary for middle-mile success across various industries. However, they prove especially beneficial in sectors with demanding service levels.

TGW Logistics: Your Strategic Partner for Middle Mile Warehouse Solutions

Optimizing the middle mile isn’t easy. It requires the right automation combined with a vision for long-term growth.

TGW Logistics makes middle-mile success possible with automated warehouse solutions and software that transform your intralogistics process from the ground up. Our industry-leading experts don’t stop until they discover the right solutions for your infrastructure.

We also understand the importance of reliable post-automation operations after your systems go live. Our Lifetime Support Services ensure optimal uptime so you get the most out of your automated systems and maximize your total cost of ownership. Whether you want the peace of mind of our on-site support experts or 24/7 remote support at your fingertips, TGW Logistics has you covered.

Contact Us Today

Ready to bridge the gap between storage and fulfillment? Contact TGW Logistics to explore your middle-mile automation options.

TGW Logistics is a foundation-owned company headquartered in Austria and a global leader in warehouse automation and warehouse logistics. As a trusted systems integrator with more than 50 years of experience, we deliver end-to-end services: designing, implementing, and maintaining fulfillment centers powered by mechatronics, robotics, and advanced software solutions. With over 4,600 employees spanning Europe, Asia, and North America, we combine expertise, innovation, and a customer-centric dedication to help keep your business growing. With TGW Logistics, it's possible to transform your warehouse logistics into a competitive advantage.