The TGW Availability Guarantee: How We Deliver Logistics Support That Performs

Why Availability Anchors Everything We Do

When your fulfillment center goes down, the costs multiply fast. Missed shipments. Idle labor. Broken promises to customers who expect their orders on time. For operations across all industries, particularly 3PL, retail, and manufacturing, unplanned downtime can cost hundreds of thousands of dollars per hour. That's why our logistics services portfolio exists: to keep your system running at peak performance.

Our Lifetime maintenance services provide the framework for long-term operational stability. At the center of that framework sits our availability guarantee, the measurable commitment that anchors our promise.

This guarantee represents the pinnacle of logistics support with our Lifetime Services offering. We stake our reputation and our revenue on hitting the targets we set.

What the LTS Availability Guarantee Actually Means

Our availability guarantee is straightforward: we commit to keeping your system ready for operation at least 98% of the time, with some contracts setting the bar at 98.5%. We set that threshold intentionally high because fulfillment operations cannot tolerate unreliable equipment. That threshold applies regardless of whether your system runs at full capacity or sits idle during slower periods. The equipment must be operational when you need it.

Think of it like renting a car. You pay for access whether you drive 500 miles or leave it parked. The rental company's job is to have the vehicle fueled and functional when you arrive. Our availability guarantee works the same way.

The specifics of our guarantee, including performance parameters, obligations, and penalty structures, are documented in our Lifetime Services Terms and Conditions.

The Industry Standard Behind the Guarantee: FEM 9.222

We calculate availability using FEM 9.222, a standard published by the European Federation of Materials Handling that defines how automated logistics systems should measure uptime. This framework has served as the industry benchmark since 1989, and organizations, including the American Society of Mechanical Engineers, have evaluated FEM standards as the European counterpart to American specifications.

Using a recognized global standard matters because it creates transparency. When we discuss availability targets with your team, we work from the same playbook that governs logistics support agreements worldwide. There are no proprietary formulas or hidden calculations. You can verify our methodology against the same industry standard, which builds credibility and clarity when negotiating contract terms.

Calculating Availability: The Engineering Behind the Metrics

Availability calculation in a complex fulfillment system requires more than simple uptime math. A single conveyor failure does not carry the same operational impact as a shuttle fleet going offline. Our controls engineers build mathematical models that assign weighting factors to every component based on its importance to overall system throughput.

A critical conveyor serving as the only path between two zones might receive a 100% weighting. One shuttle among thousands operating in a redundant fleet might carry a weight of 0.0001%. These factors reflect real operational reality. When we calculate availability, we measure against what actually affects your ability to move product.

The model accounts for structured equipment lists segmented by system area, weighting hierarchies, and the specific configuration of your installation. This same methodology applies whether we manage a brand-new system or provide maintenance for aging sites that have evolved over decades of operation.

From Sensors to Dashboards: How Data Moves Through the System

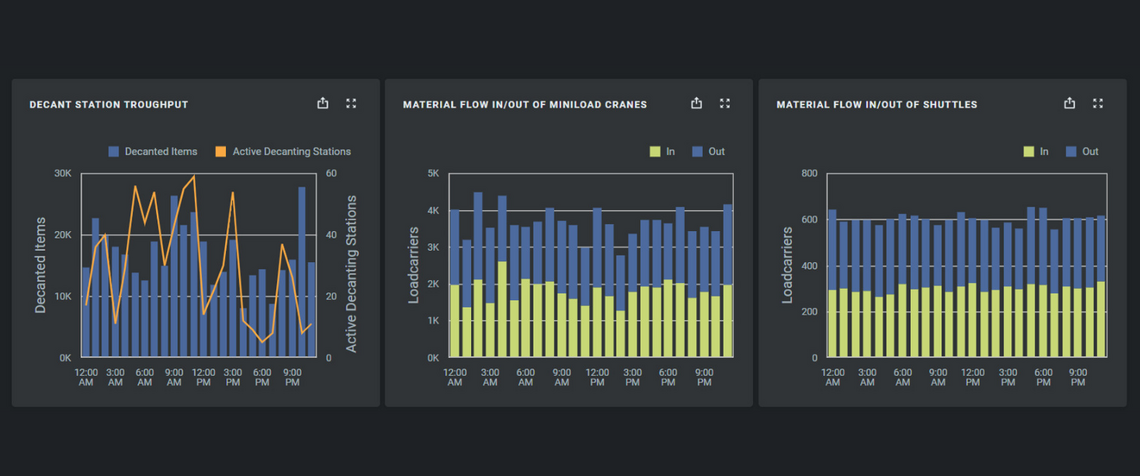

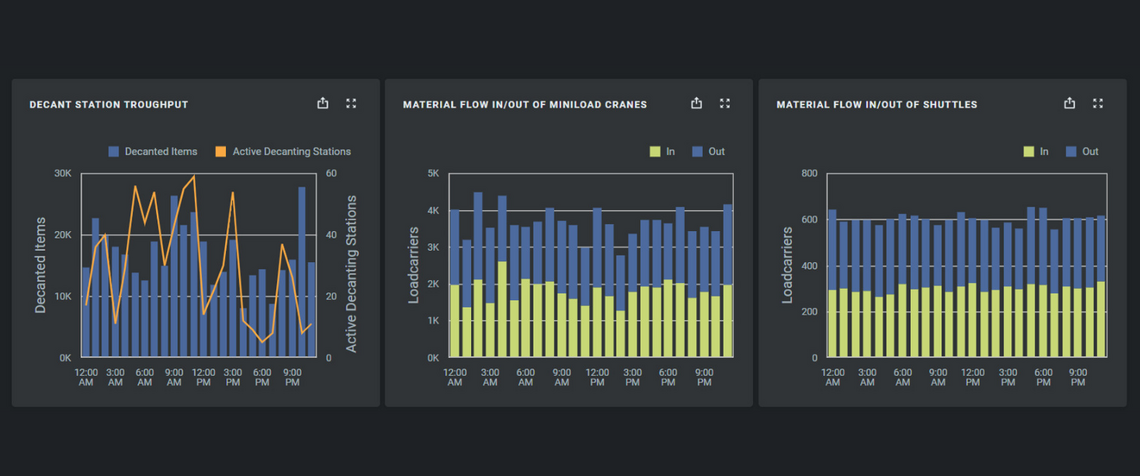

Every availability calculation starts with data, and our SCADA (Supervisory Control and Data Acquisition) systems capture that data continuously. Sensors throughout your installation monitor equipment status, feeding information through Modbus gateways that bridge field devices to your facility's network infrastructure. When something goes wrong, the system generates an automatic alarm.

These alerts log to the second, creating a complete historical record of every fault, every recovery, and every minute of uptime across your operation. Dashboards visualize this information by system zone, giving both our team and yours real-time visibility into performance trends and long-range analysis of system health. You can see exactly where issues cluster, how quickly they resolve, and how availability tracks against guarantee thresholds over any time period you choose.

Human Expertise: How Faults Are Categorized and Classified

Automated alerts tell us something happened. Human expertise determines what it means for your availability calculation.

When a fault triggers in the system, our team reviews the event and classifies it according to established categories. Some issues count against availability: system errors, mechanical failures, and reactive maintenance all reduce your uptime percentage. Other events do not count: planned maintenance performed during scheduled windows, product-related issues like jammed cartons, and external factors such as unstable inbound power fall outside the availability calculation.

This classification process happens transparently. Our teams work alongside yours to validate how faults are categorized, ensuring both sides agree on what counts and what does not. That joint accountability eliminates disputes when performance reviews come due.

Why Redundancy Matters: Designing for High Availability

Availability starts long before the first fault alert fires. It begins in system design.

We engineer redundancy into critical pathways wherever possible. Multiple shuttles operating in the same aisle means one failure does not stop picking. Duplicate conveyors in high-traffic zones keep product flowing even when maintenance pulls a line offline. Redundant lifts ensure vertical transport never becomes a chokepoint.

Single points of failure pose the greatest risk to availability. When one corridor serves as the only connection between major system areas, any issue in that zone threatens the entire operation. We have seen installations where a single pathway carries hundreds of millions of dollars' worth of throughput risk. Designing that vulnerability out of the system protects availability far more effectively than any reactive maintenance program ever could.

Every design choice we make with your team considers how it will affect logistics support across the system's full lifespan, keeping your operation prepared for seasonal surges when downtime is most severe.

How TGW Hits the Guarantee: The Lifetime Services Ecosystem

No single service protects availability on its own.

Our Lifetime Services portfolio operates as an integrated ecosystem, with each component reinforcing the others.

- On-site maintenance teams stationed at your facility catch issues before they escalate.

- Field services provide flexible expert support during seasonal peaks or corrective actions.

- Spare parts programs ensure critical components stay in stock, eliminating the wait times that turn minor faults into extended outages.

- Training and certification keep your operators skilled in proper system use, reducing errors that trigger unnecessary faults.

- Health and safety systems protect both your team and your equipment from preventable incidents.

- Remote services provide 24/7 access to our experts, accelerating diagnosis and resolution.

- Condition-based maintenance uses real-time performance data to predict failures before they occur.

- Retrofit and extension services keep aging systems current as your business evolves.

- Consulting services deliver performance analysis and optimization recommendations.

Our nimble logistics support model brings speed and flexibility to every engagement across all industries, particularly 3PL, retail, and manufacturing operations. With more than 1,100 service experts deployed globally, we position resources close to your operation so response times stay short.

Every practice, every program, and every expert in our network aims at one target: stable availability performance that meets or exceeds your guarantee threshold.

The Financial Commitment: Penalties, Bonuses, and Skin in the Game

Talk is easy. Financial commitments prove confidence.

We are so confident in our systems that we often include a contractual financial penalty if the availability falls below guaranteed thresholds. We accept that exposure because we stand behind our systems and our teams.

Some agreements also include bonus structures that reward performance exceeding targets. When we beat the guarantee, both sides benefit. This alignment of incentives creates genuine partnership rather than adversarial vendor relationships.

Few automation providers will tie their compensation directly to availability outcomes. We do it because accountability strengthens relationships, and strong relationships sustain successful fulfillment operations over years and decades.

Why It Matters for Your Organization

The availability guarantee translates directly into benefits your organization can measure.

Operations leaders gain predictable throughput they can plan around. When your system consistently hits 98%+ availability, you can make capacity commitments to customers with confidence. Finance teams appreciate predictable costs and reduced risk of surprise downtime expenses. Warehouse managers gain peace of mind knowing the equipment they depend on comes with contractual protection and a partner invested in keeping it running.

For 3PL providers juggling multiple client SLAs, retail operations facing intense holiday seasons, and manufacturers running lean production schedules, availability is the foundation everything else rests on.

If you want to understand how our logistics support approach applies to your specific operation, our Lifetime Services team can walk you through an availability analysis tailored to your system.

Your Partner for Long-Term, High-Availability Operations

Our availability guarantee functions as a promise backed by engineering rigor, real-time data, transparent methodology, and financial accountability. It represents our commitment to your success, measured and verified against the same standards used across the global logistics industry.

When you partner with TGW Logistics for Lifetime Services, you gain more than maintenance coverage. You gain a team that stakes its reputation on keeping your operation running. For 3PL providers, retailers, and manufacturers seeking logistics services that deliver measurable Logistics Support outcomes, the conversation starts here.

Connect with our services team to discuss your operation and explore what a lifetime partnership looks like.

TGW Logistics is a foundation-owned company headquartered in Austria and a global leader in warehouse automation and warehouse logistics. As a trusted systems integrator with more than 50 years of experience, we deliver end-to-end services: designing, implementing, and maintaining fulfillment centers powered by mechatronics, robotics, and advanced software solutions. With over 4,600 employees spanning Europe, Asia, and North America, we combine expertise, innovation, and a customer-centric dedication to help keep your business growing. With TGW Logistics, it's possible to transform your warehouse logistics into a competitive advantage.