TGW Logistics appointed to design and implement fulfillment solution for LKQ (Fource)

Highly automated FlashPick® System

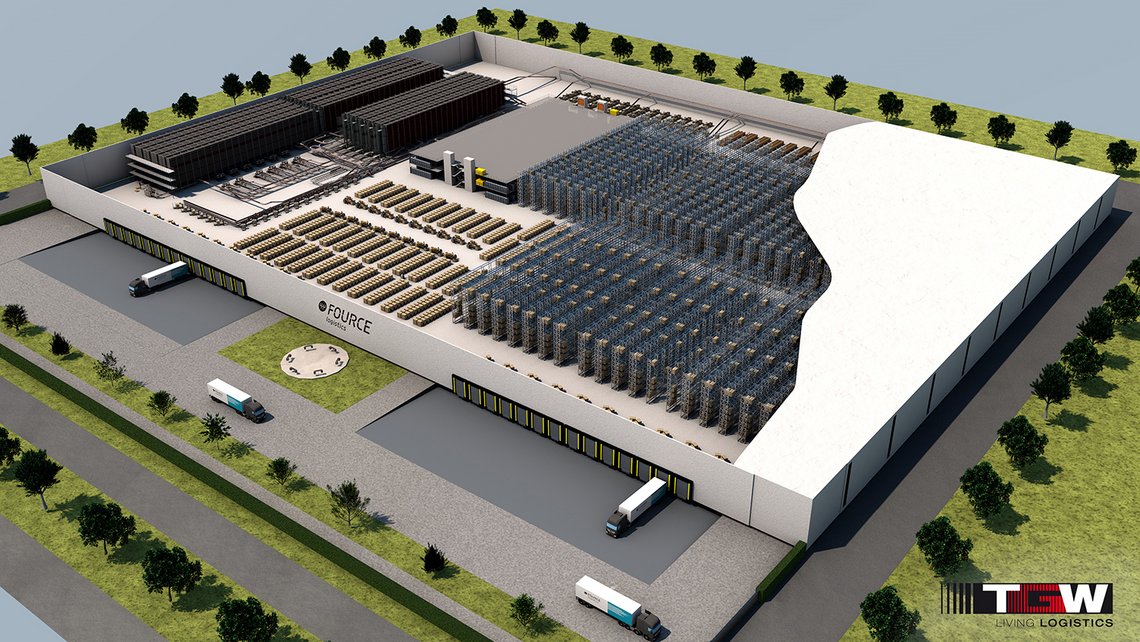

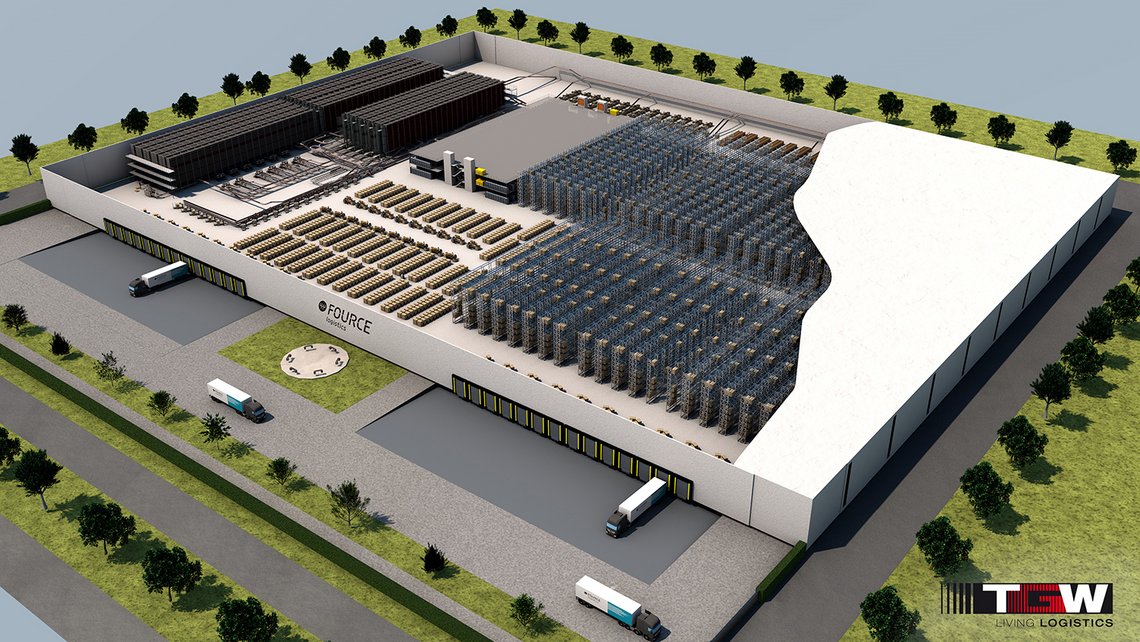

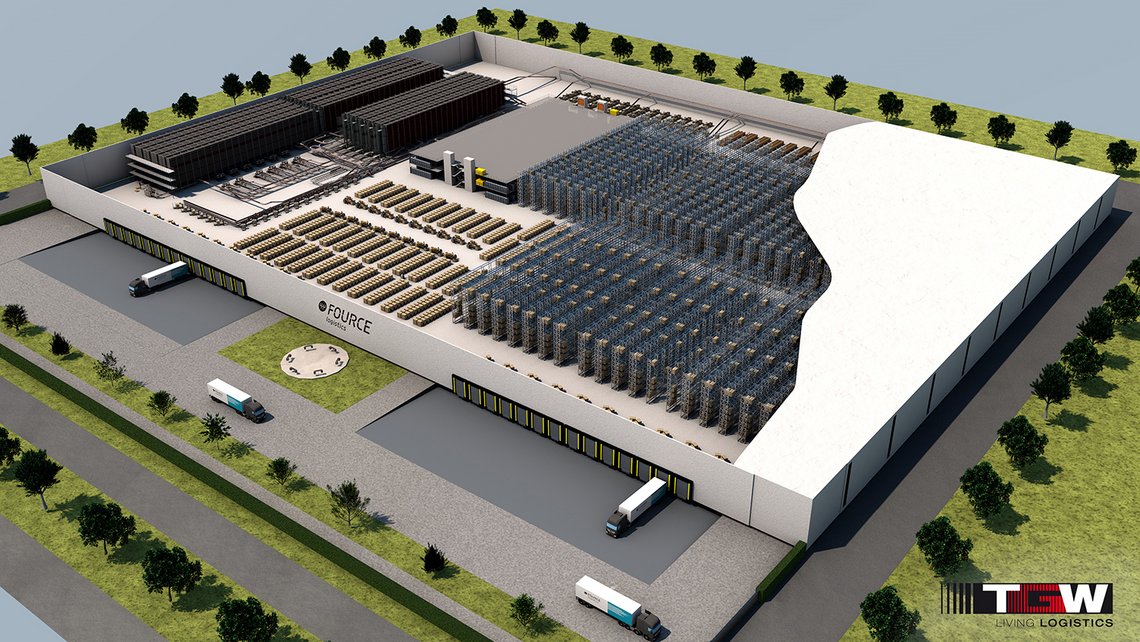

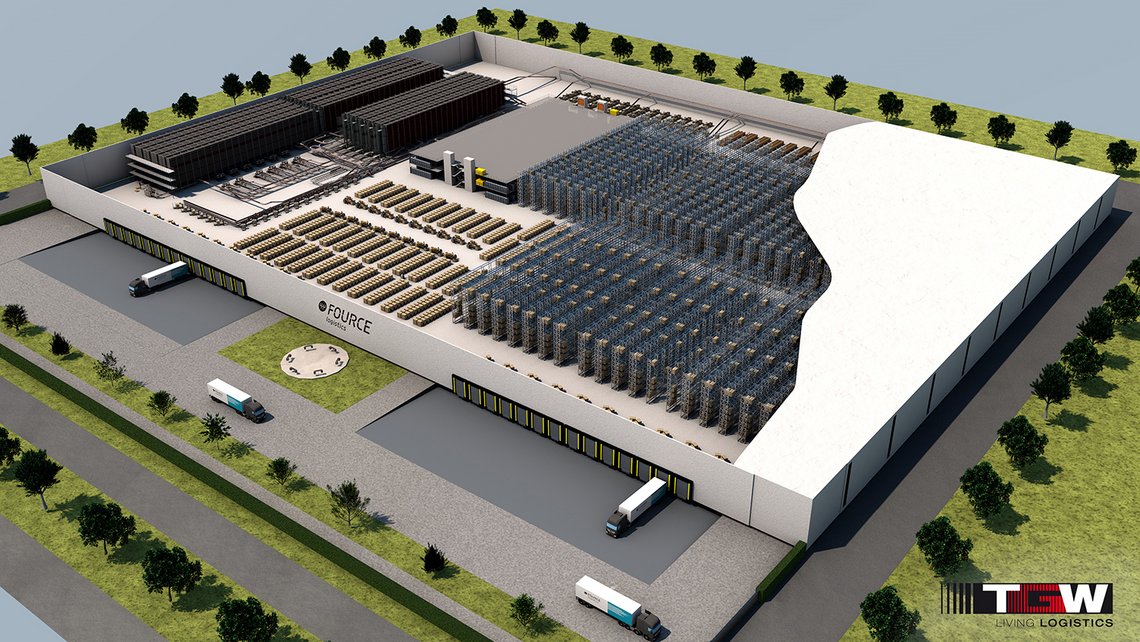

TGW Logistics is implementing a highly automated fulfillment solution in Berkel and Rodenrijs for LKQ, formerly known as Fource, a Netherlands-based automotive spare parts specialist. By implementing this solutions, LKQ is centralizing its warehouse operations in one location and taking an important step in optimizing the supply chain. Furthermore, this is the foundation for the planned growth for the next years. Construction of the building started in December 2019, with the FlashPick® system slated to go live as planned in autumn 2021.

LKQ group and sells automotive spare parts, tools and components using a network of wholesalers. The core markets of the company, which has 3,000 employees, are the Netherlands and Belgium. Recently, the spare parts specialist appointed TGW logistics to design an implement and end-to-end fulfillment solution for their Greenfield logistics hub. 'This is an important order and a fantastic parts and components reference for TGW Logistics' underscores David Hibbett, CSO at TGW Northern Europe.

Optimized supply chain

The new building, with a 50,000 m² footprint, centralizes LKQ's fulfillment processes for the Netherlands in one facility. Due to its spectacular architecture, the fulfillment center is called 'The Bridge', and is a symbol of the combination of people and technology.

Powerful and flexible

FlashPick® is the core of the highly automated solution – with ten aisles and more than 180,000 tote storage locations. More than 200 energy-efficient Stingray shuttles ensure storage and retrieval. In combination with twelve goods receiving workstations and 16 high-performance PickCenter One workstations, the shuttle system is the centerpiece of the system.

The TGW Logistics Software Suite is responsible for Warehouse Management including Warehouse Control System (WCS) and Material Flow Controller (MFC). TGW Logistics Commander is responsible for the control system. Special machines for automatically putting cartons upright and closing them, tote stackers and lifts are also part of the scope of supply.

Lifetime Services

During live operation, LKQ relies on TGW Logistics' expertise. A team of Lifetime Services specialists works together with the customer's technicians to ensure maximum availability.

Press Release & Render

TGW Logistics is a foundation-owned company headquartered in Austria and a global leader in warehouse automation and warehouse logistics. As a trusted systems integrator with more than 50 years of experience, we deliver end-to-end services: designing, implementing, and maintaining fulfillment centers powered by mechatronics, robotics, and advanced software solutions. With over 4,600 employees spanning Europe, Asia, and North America, we combine expertise, innovation, and a customer-centric dedication to help keep your business growing. With TGW Logistics, it's possible to transform your warehouse logistics into a competitive advantage.