- Increased service level, decreased logistics costs and improved ergonomics for the employees as primary advantages.

- Robots will handle erecting, closing and sizing shipping cartons.

- The project marks the beginning of a long-term collaborative partnership.

Bausch + Lomb commissions TGW Logistics to automate its fulfillment center

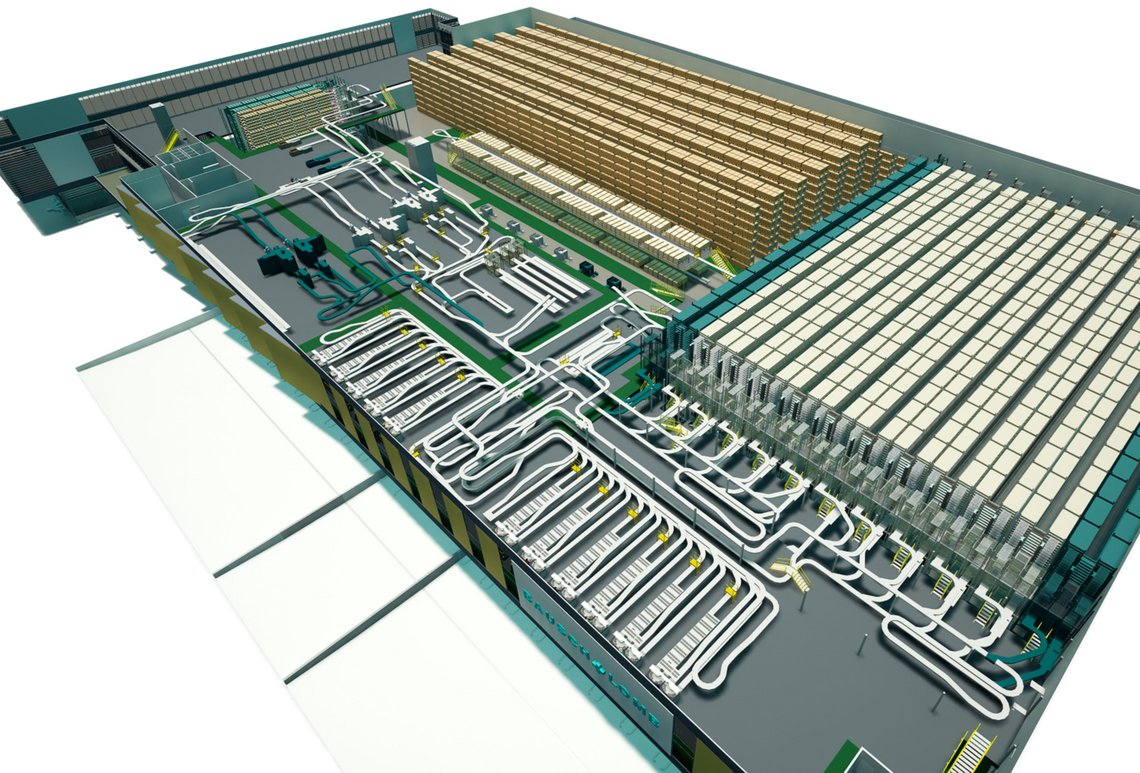

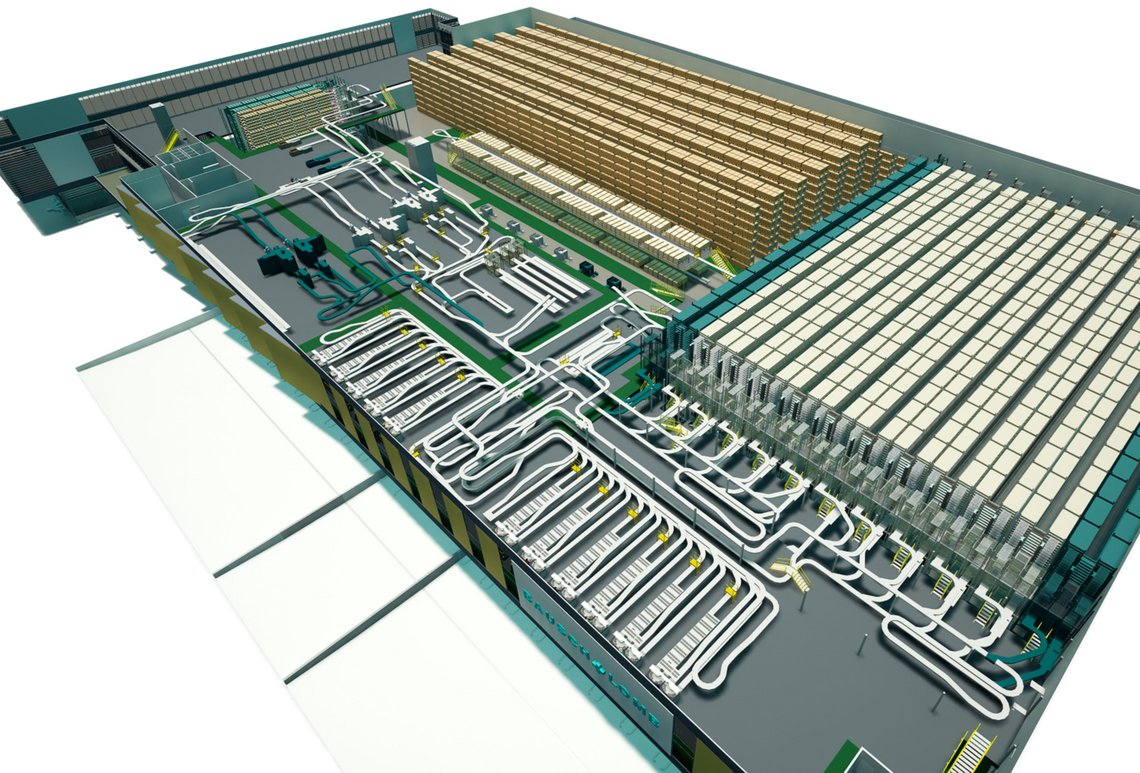

(Marchtrenk, Austria, 30 September 2025) In the Dutch municipality of Aalsmeer, roughly 13 kilometers southwest of Amsterdam, TGW Logistics is erecting a highly-automated distribution center for Bausch + Lomb to be completed by the fall of 2027. Among other benefits, the high-performance Goods-to-Person solution will optimize the healthcare specialist's service level and reduce logistics costs, all while improving ergonomics for the employees.

In 1853, J. J. Bausch opened a small optician's shop in Rochester, New York. In doing so, he laid the cornerstone for one of the oldest still-active companies in the United States and kicked off a story of success in the medical technology sector. Today, Bausch + Lomb is among the leading manufacturers of technology-oriented eye products including contact lenses, surgical instruments and pharmaceuticals. The healthcare specialist is active in over 100 countries, employs roughly 13,500 people and generated a revenue of 4.8 billion US dollars in 2024.

Growth as a driver of automation

Since their current intralogistics system was being stretched to its limits with increasing regularity, Bausch + Lomb was on the lookout for a future-proof alternative. Only a system customized to their individual needs would be able to cope with the growth they have planned for the coming years. With a range of products intended for the medical technology sector, the quality standards for this project were particularly high.

Start of a shared journey towards automation

Following an intense planning and analysis phase, the healthcare experts put their trust in the expertise and experience of TGW Logistics.

"We are delighted to be working together with Bausch + Lomb. Our customer was looking not only for a supplier, but for a long-term strategic partner," stresses Bart Van Eycken, Director of Sales for the Customer Unit North Europe at TGW Logistics. "As a foundation-owned company, TGW Logistics is a stable and reliable partner with a strong focus on corporate culture and values."

Shuttle warehouse as the high-performance centerpiece

The core element of the solution in Aalsmeer is a shuttle system with more than 150,000 storage locations. Double-deep storage will allow efficient use of the available space; 300 robots will store and retrieve up to 8,700 totes per hour. Customer orders will be picked at ergonomic high-performance workstations.

In the packing area, robots will handle the automatic erecting and lidding of the cartons. In the next step, a sizing machine will reduce them to the necessary height, keeping the volume (and therefore also the shipping costs) to a minimum. The shuttle warehouse will serve as a buffer for orders until the cartons continue to the automatic palletizing area and finally to dispatch.

![[Translate to China:] TGW press release Bausch + Lomb](/fileadmin/_processed_/6/1/csm_TGW-press-information-Bausch-Lomb_a79b85e84a.png)

![[Translate to China:] Rendering of the Fulfillment Center [Translate to China:] Rendering of the Fulfillment Center](/fileadmin/_processed_/c/6/csm_Bausch-Lomb-Render-1_ee9bc28bf5.jpg)