“We know how our business works, and we knew that our growth would result in a logistics centre that did not suit our needs anymore. We always have to think about our future, and the TGW logistics centre was a solution that provided us with both: capacity and performance.”

Conrad Electronic

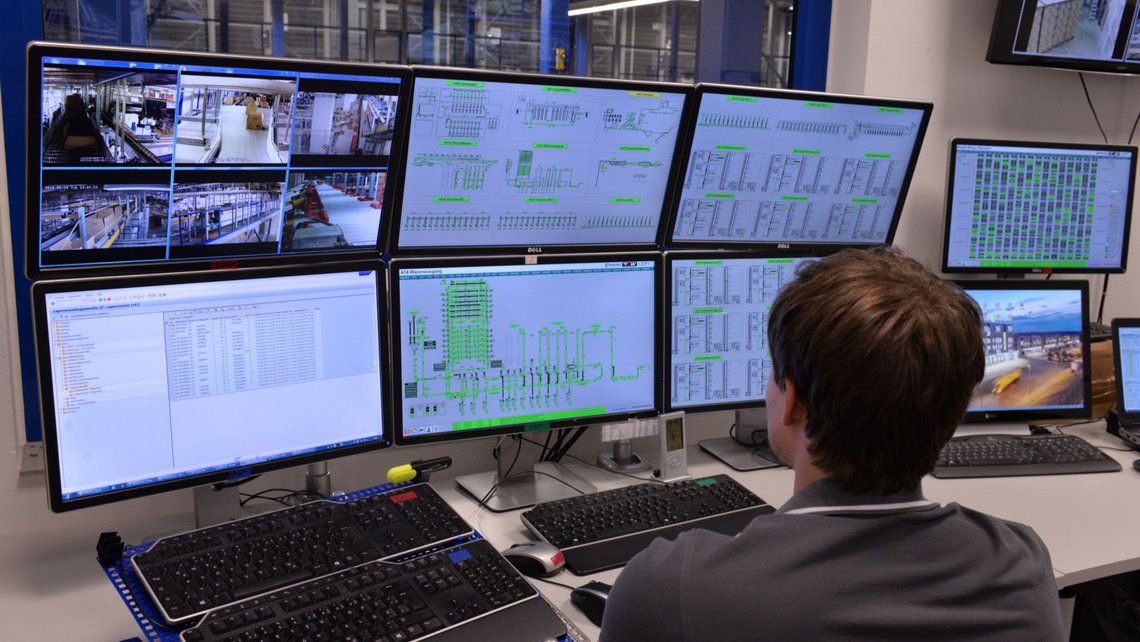

![[Translate to UK:] Parcels on a conveyor belt inside a modern logistics center](/fileadmin/_processed_/1/d/csm_Conrad-consumer-goods-case-study-conveyor_62d65e1018.jpg)