![[Translate to UK:] Visibly frozen, fresh goods such as fruits and vegetables in a colorful selection](/fileadmin/_processed_/2/3/csm_Coop-grocery-case-study-header_85ed18aa2e.jpg)

![[Translate to UK:] Visibly frozen, fresh goods such as fruits and vegetables in a colorful selection](/fileadmin/_processed_/2/3/csm_Coop-grocery-case-study-header_85ed18aa2e.jpg)

Coop

& TGW Logistics

Automating Coop’s Deep Freeze DC & Cold Chain Logistics Processes

Robust warehouse automation

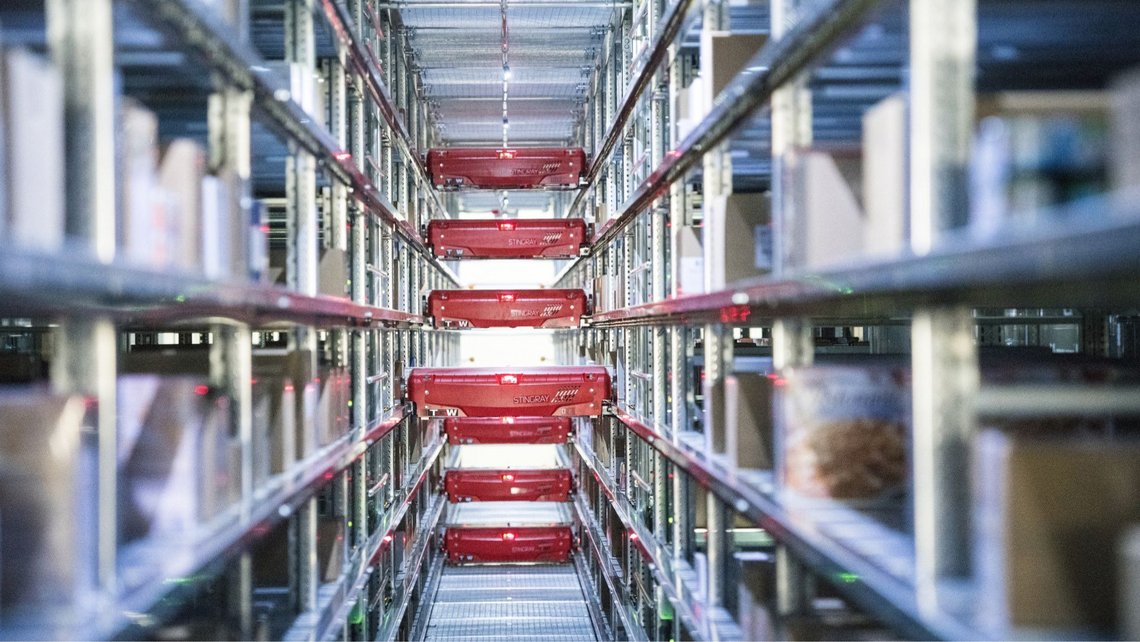

The Swiss grocery retailer Coop supplies its national retail stores from its central deep freeze distribution centre in Schafisheim, Switzerland. Since working in a deep freeze environment is particularly challenging for human workers, Coop's solution boasts our robust warehouse automation. Our technologies allow varied temperature zones for the preservation of different perishable goods. In keeping with the motto "only as cold as necessary," the temperature ranges between -5°C during the depalletising and palletising process down to -23°C in the shuttle warehouse. The fully automated solution is compact, energy efficient, and reduces strain on human workers.

Key Benefits

- Smaller Footprint and Lower Energy Costs: The compact system design results in maximal supply chain optimisation. The goods in the deep freeze warehouse are stored in high-density racking, reducing energy costs.

- Store-Friendly and Volume-Optimised Packing: Automated palletising robots prepare store orders on ready-to-ship pallets. The robot can palletise based on an optimised, pre-cubed pattern, requiring less space—cutting transportation costs. In addition, the items are stacked in a store-friendly manner, so retail employees require less effort and time to shelve delivered items.

Solution and Material Flow

The end-to-end solution provided by TGW Logistics is comprehensive. It depalletises frozen goods, stores the individual units in the shuttle system, and finally sequences the items for mixed-carton palletising - all fully automated.

Highlights

Zero-Touch Picking

Depalletising robots allow for fully automated picking (Autostax), significantly reducing employee time in a physically taxing, deep-freeze environment.

Lifetime Services

TGW Logistics Lifetime Services allows for efficient operations and a high-volume fulfilment capacity. The TGW Logistics On-Site team works closely with the Coop team to virtually eliminate downtime and guarantee that all processes work to specification.

Stay ahead of your competition through automation!

Speak with one of our representatives today to learn how automation by TGW Logistics transforms businesses into profitable enterprises that outpace the competition.

Contact us today

Michael Schedlbauer

Vice President Business Development Grocery

TGW Logistics is a foundation-owned company headquartered in Austria and a global leader in warehouse automation and warehouse logistics. As a trusted systems integrator with more than 50 years of experience, we deliver end-to-end services: designing, implementing, and maintaining fulfilment centres powered by mechatronics, robotics, and advanced software solutions. With over 4,600 employees spanning Europe, Asia, and North America, we combine expertise, innovation, and a customer-centric dedication to help keep your business growing. With TGW Logistics, it's possible to transform your warehouse logistics into a competitive advantage.