Maximum Quality, minimum space

TGW Robots are accompanying the appliance brands Bosch and Siemens into the future

To improve people's quality of life with its products – this is the goal of BSH Hausgeräte GmbH. Celebrating its 50th birthday this year, Europe's largest appliance manufacturer has acquired a new intralogistics system with robots from TGW Robotics. A lot goes on behind the scenes of the compact system, which takes up just 150 square metres, and the same could be said about the BSH story of success.

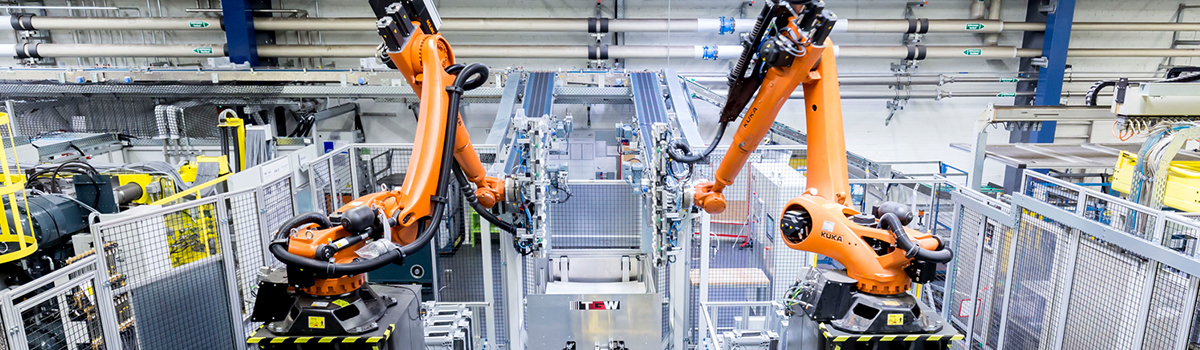

Since its foundation as a joint venture company by Robert Bosch GmbH and Siemens AG in 1967, BSH Hausgeräte GmbH went from being a German exporter to the second largest appliance manufacturer in the world. Continuous increases in turnover and staffing are testament to the success of the company strategy. In roughly 40 factories around the world, BSH manufactures state-of-the-art appliances, the company's goal being to improve the quality of life of its customers with its range of products. To be able to continue to ensure this quality, new, higher-performing processes were needed. At the BSH site of Dillingen in Germany, two six-axle robots from TGW Robotics took over the tasks of sorting and handling the base supports for dishwashers as well as their removal and buffering. They now also take care of the subsequent loading onto containers.

Over the course of the restructuring of the base support production, the company invested heavily into acquiring new injection moulding machines and implementing pioneering and sustainable automation.

Robotics for best performance

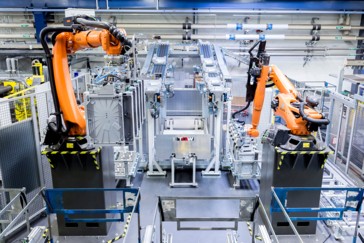

In 2016, TGW Robotics was commissioned as the prime contractor for the construction of a so-called stacking station worth several hundred thousand Euros. Sebastian Feistl, Design Engineer at TGW Robotics, explains: "The point of reference was a similar system, but with a higher cycle time and a product range in need of minor processing. This system was completely demolished and replaced with our new one." A link to the injection moulding machines was also required, the number of which doubled from three to six. This presented the teams with an additional challenge. "For the new system, we only had 150 square metres of space! So you can imagine the extremely narrow parameters we were given for the planning, design and, ultimately, the implementation. A fully automatic detection and distribution process for the base supports of the dishwashers at four completely independent workstations also had to be integrated."

Thanks to the implemented process for component detection, all the existing base support tools can now be distributed across all the new injection moulding machines of the interconnected system, regardless of their version.

This allows several base supports to be produced fully automatically at the same time and then sorted and stacked on the transportation systems. The processes are visually shown on screens in a manner that is user-friendly.

The transport of the base supports and the containers, which are also provided automatically via the system, was thus implemented at the request of the customer. The heart of the system is the robot cell with two six-axle robots.

Domestic robots

So how do these proverbial domestic robots actually work? "A pre-defined hole pattern allows the robots to detect the various base supports. The robot can thus sort and then gather identical base supports into a package of 10 in one magazine," explains Feistl. The two robots interact with one another within a very small area. "Naturally this is a safety area, accommodated for by our proven safety technology". TGW Robotics is particularly proud of its gripper technology, which was also employed at BSH to ensure optimum performance and precise processes. "For this, we used a multi-purpose gripper to handle the individual base supports. In this way, the robot can gather the 10-piece packages and temporarily store them. Every millimetre counts here – not just in the handling of components, but also in the external utilisation of the robot range in the smallest space!"

Good things come in small packages!

BSH was able to achieve great things in a small space: performance was significantly enhanced and the customer can now process a greater range of products in Dillingen. "We are delighted that our technology can perform so well in such a small space. We are proud of our successful customers and of what we have achieved together," says Feistl.

The professional implementation of the defined processes on the part of TGW was the foundation for the successful introduction of the new stacking station.

With the new stacking concept, the strategic structuring met the high quality requirements of the in-house production. The interlinking of the existing machines and the new injection moulding machines meant that the existing value flow could be optimised and new synergy effects created. Digitalisation as the basis for Industry 4.0 was also driven forward.

|

Find out more about... | ||

ROBOTICS AND AUTOMATION |

SOLUTIONS FOR SPARE PARTS AND COMPONENTS |

360° LOGISTICS SOLUTIONS BY TGW |