- New joint project only months after realising the first fully automated fulfillment center

- Project in Oberhausen for the largest food eFulfillment centre in Germany

- TGW robots automatically load the transport frames for the delivery vehicles

(Marchtrenk, July 13, 2022) The Dutch online supermarket trusts in the expertise and experience of intralogistics specialist TGW once more. In the German town of Oberhausen, North Rhine-Westphalia, a powerful fulfillment center will be built by summer 2024, securing Picnic's further growth on the German market. Both companies are linked by a close collaboration: only months ago, their first jointly planned and implemented project, a logistics centre in Utrecht, celebrated its go-live.

Picnic was launched in Amersfoort in 2015 and has evolved into one of the leading European eGrocery suppliers within just a few years. The growing online supermarket with superior service is currently active in the Netherlands, Germany as well as France. Orders can be placed using an intuitive app, groceries are delivered using eco-friendly electric vehicles.

If you order before 10 PM, fresh, chilled and frozen groceries will be delivered right to your door the next day. Thanks to the so-called "milkman principle", the delivery is precisely on time and for free.

Three temperature zones ensure highest product quality

To continue its expansion on the German market, Picnic takes the next step and builds a highly automated fulfillment center in the heart of the Ruhr area.

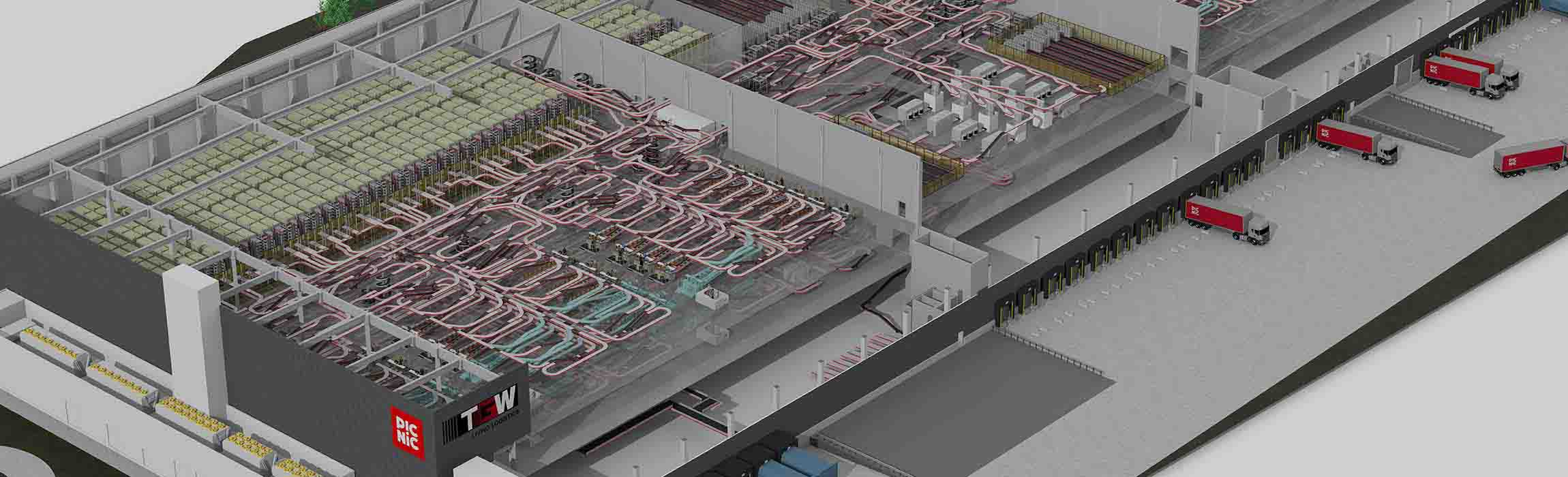

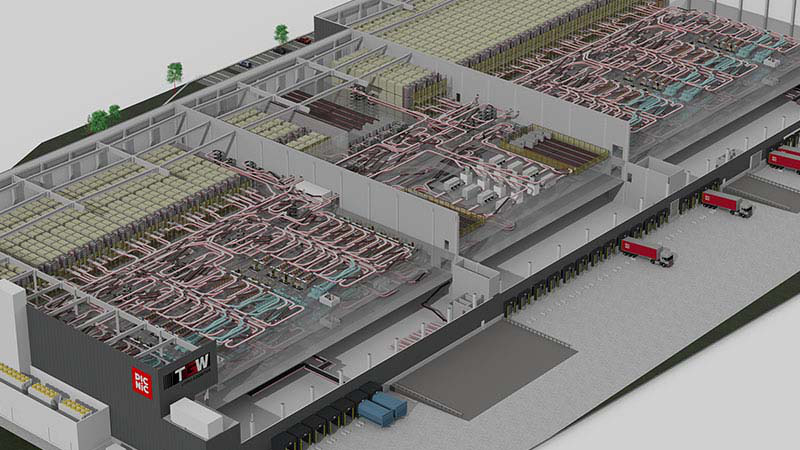

TGW's plans involve a FlashPick® system, which is powerful, reliable and extremely flexible and thus enables the best customer service at a high level of efficiency. A shuttle warehouse with 40 aisles is at the heart of the system: grocery and non-grocery items are stored at three different temperature ranges, from 20, 4 to -25 degrees Celsius.

Robots load the transport frames

Customer orders either start at one of more than 60 PickCenter One workstations or in the Zone-Picking area – these are mostly products with a large volume and fast-moving items. Then, the orders are consolidated in an automated buffer.

Shortly before the lorries leave to go to the local distribution points, items are retrieved towards a robot-assisted system developed by TGW, which loads the totes with the customer orders into the transport frames fully automatically, thereby creating more efficiency.

Highly robotised

Thanks to the great performance of the FlashPick® system, and the Picnic algorithms, the amount of orders that can be processed per hour are best in class. "The project in Oberhausen is another milestone and marks the next level of our cooperation with Picnic. Their renewed proof of trust is a great acknowledgement of our close collaboration", Hans De Sutter, Managing Director TGW Benelux, is pleased to announce.

Frederik Nieuwenhuys, co-founder of Picnic adds: “TGW has been a great partner in co-creating this best-in-class facility. The combination of the Picnic tech team and the TGW technology shows that we can lead the industry to provide even better service to our clients.