- Highly automated solution gives shipping capacity a big boost

- Rovolution order-picking robot heralds new age in picking for workwear specialist Engelbert Strauss

- 26 autonomous mobile robots (AMRs) play a central role in return handling

- The two companies are linked by a longtime collaborative partnership

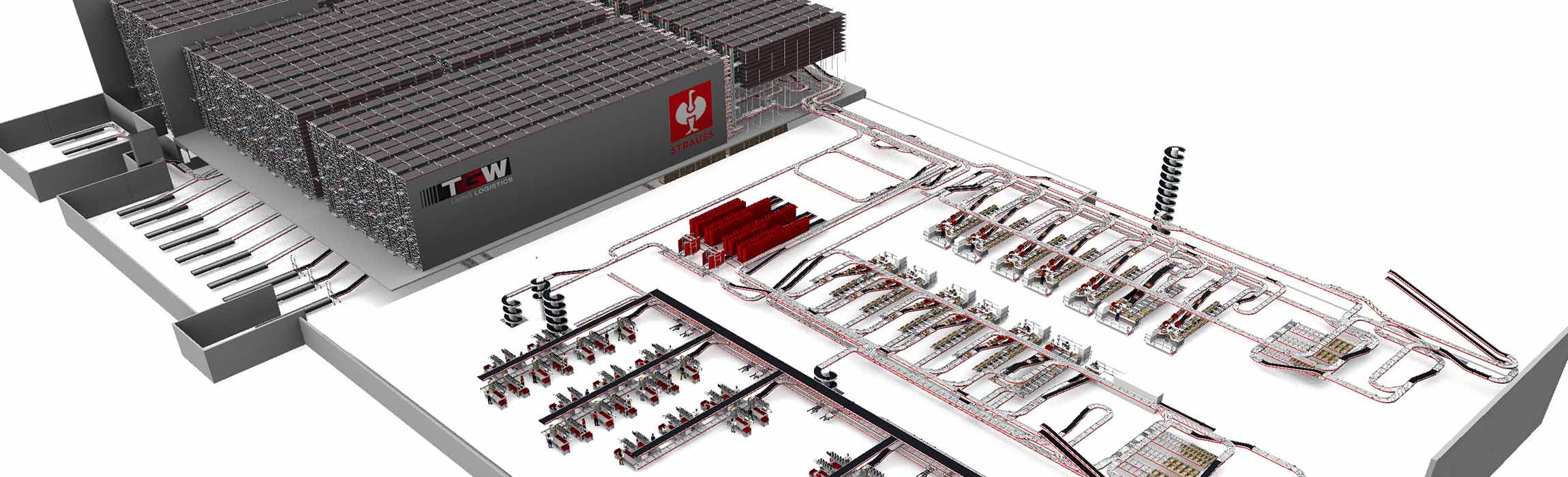

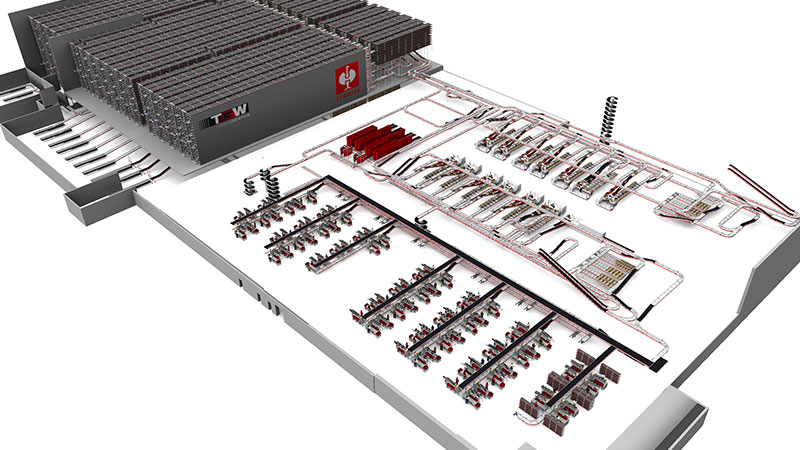

(Marchtrenk, November 22, 2021) In the Hessian town of Biebergemünd, TGW is setting up another high-performance hub for Engelbert Strauss, which will be completed by the end of 2024. This is already the second system built for the workwear specialist within three years. The existing system is being replaced by a highly automated shuttle solution, with all renovation work taking place during ongoing operations. This will allow Engelbert Strauss to give its shipping capacity a substantial boost.

A family-owned company founded in 1948, Engelbert Strauss is one of the world's leading workwear and utility wear manufacturers. The collections with the highly recognisable red and white logo are designed for professional use and mostly delivered to customers in skilled trades, industry and service, but also to customers from the B2C segment.

Collaborative partnership

Engelbert Strauss and TGW have been intralogistics partners for years. The CI Factory in the Hessian town of Schlüchtern went online in August 2020. An investment of hundreds of millions of euros was made in this facility. This is the most state-of-the-art omni-channel logistics platform for workwear and work footwear in the world. The shuttle-based TGW FlashPick® system enables dispatch of 50,000 or more packages per day, ensures reliable next-day delivery and links the various sales channels to each other efficiently.

The new project at the workwear specialist's headquarters in Biebergemünd helps to strengthen the partnership: TGW is replacing the existing system with a high-performance shuttle solution by the end of 2024, and this solution can substantially boost the shipping capacity. The CI Factory will continue to serve as the central inventory warehouse for more than 40,000 different articles and is in charge of omni-channel order fulfilment. In the future, it will also serve as the replenishment warehouse for the order picking system in Biebergemünd.

Trusting in the expertise of TGW

"Engelbert Strauss relies once again on the competence and experience of TGW as a general contractor and solutions provider for the intralogistics system", says Johann Steinkellner, CEO Central Europe at TGW. "We could not be more pleased about this expression of Engelbert Strauss' trust in us. It is a wonderful affirmation of our close collaboration and underscores that we are Engelbert Strauss' partner of choice."

Matthias Fischer, Head of Operational Projects at Engelbert Strauss, explains the vote of confidence, saying, "Why have we placed a second major order with TGW in such a short time? I get asked this question all the time. Because it involves simultaneously modifying the existing system and ensuring that customers continue to be reliably supplied with Strauss products, the planned project is very complex and requires partners who are 100 percent reliable and experienced. Partners who are immersed in the Strauss world and its mindset. We have found this partner in TGW. That's why we are confident that the project in Biebergemünd will be just as successful as the one in Schlüchtern."

Rovolution order-picking robot heralds new age in picking

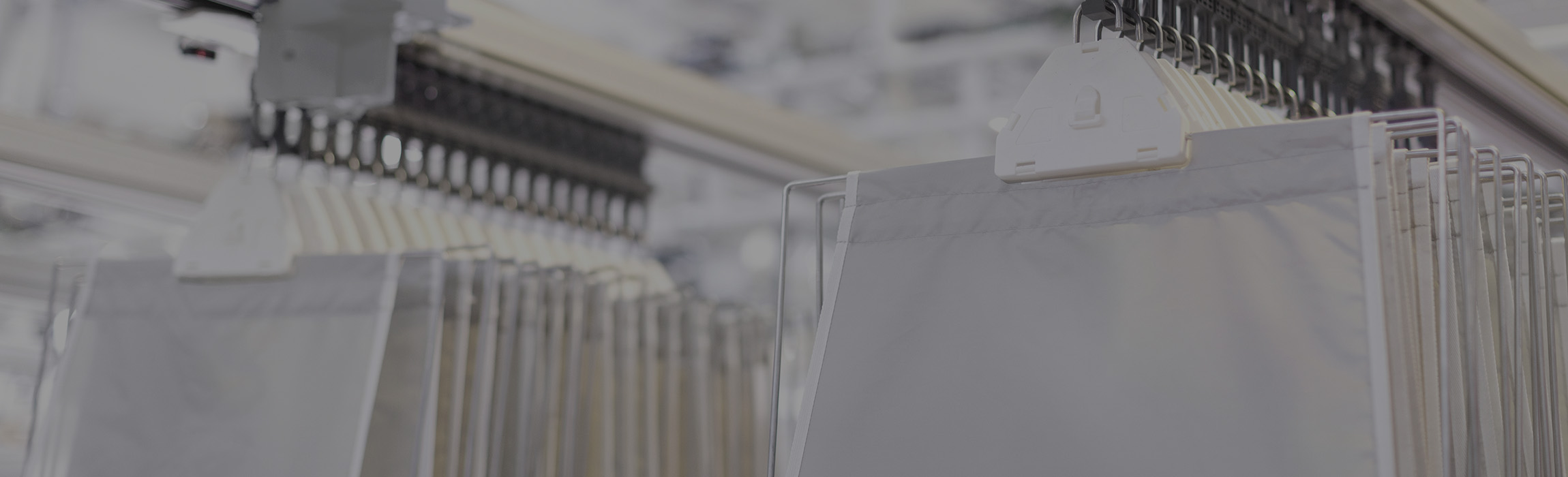

The project in Biebergemünd includes a 17-aisle shuttle warehouse with 25 order picking workstations and the Rovolution PickCenter as a highlight. The intelligent, self-learning robot picks SKUs of different sizes, shapes and surface qualities fully automatically and with maximum performance. Unexpected events are corrected autonomously and without human intervention, which allows for uninterrupted operation around the clock. Decorated with the "Austrian Robotics Award" and the "German Innovation Award", the picking robot ushers in a new age of order picking for Engelbert Strauss.

The incoming and outgoing goods areas and downstream special processes are also being redesigned. Energy-efficient KingDrive® conveyors connect the different functional areas with each other.

AMRs for handling of returned goods

Another highlight: a fleet of 26 intelligent autonomous mobile robots (AMRs) supplies the returned goods workstations at the fulfilment centre with empty totes and totes filled with returned goods—autonomously and without human intervention. At the CI Factory in Schlüchtern, Engelbert Strauss has already spent over a year gaining experience with the autonomous robots as part of a pilot project. Working together, the partners are now tackling the next steps regarding the use of the innovative technology.