- Highly efficient TGW system for chilled products

- Faster delivery and lower costs through high degrees of automation

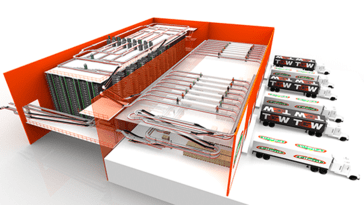

In a big event, Fileni opened its new distribution center in the central Italian community of Cingoli. The national distribution hub is now in a position to sustainably accelerate delivery processes for the poultry specialist thanks to its high degree of automation. Within 18 months, TGW realized this highly efficient system for chilled products.

With a turnover of 340 million euros and 1,800 employees, Fileni is the third largest producer and marketer of poultry in Italy – and the largest one when it comes to poultry from organic farming. The company is active in business-to-business and supplying major customers and supermarkets. Fileni is pursuing an ambitious growth course and intends to expand even more in coming years. Their new intralogistics system is the footing for this.

Accelerated delivery, lower costs

At the core of Fileni’s intralogistics solution provided by TGW is a carton shuttle warehouse with four aisles and 110,000 storage slots. More than 100 energy-efficient Stingray shuttles move along 27 levels, thus ensuring quick storage and retrieval at temperatures from 0 to 4 degrees Celsius in order to ensure optimum cooling conditions for the poultry, which is highly sensitive. Orders are then transported from the shuttle warehouse to the labelling lines, where they are labelled with the required product information details and then sequentially moved to the palletizing system. In addition, Fileni also relies on TGW’s software competence: The intralogistics specialist is also responsible for both Fileni’s warehouse management system (WMS) as well as the controls systems.

TGW supports growth through automation

TGW’s high-performance system has a throughput capacity of about 5,000 cartons per hour. Thanks to highly automated processes and the resulting reduction in manual workflow, Fileni can now considerably accelerate delivery. One of the top contributing factors is the concept of directly linking production to warehousing. The system improves productivity, reduces costs, and also meets highest standards in terms of workplace economics.

“The extremely high degree of automation will enable Fileni to lower process costs and increase efficiency per operator. Thus, the company is ideally positioned for further growth“, says Matteo Righini, Managing Director at TGW Italia.