- TGW FlashPick®: Ideal solution for rapid product-line changes

- Up to 30,000 orders per day

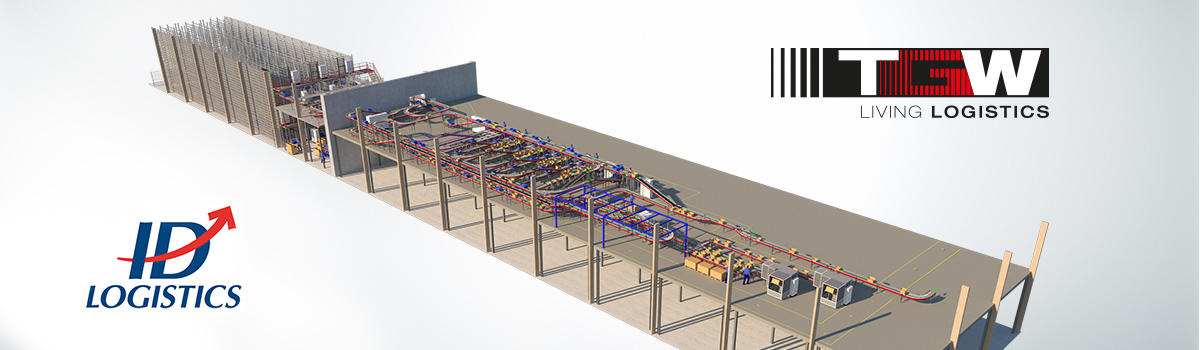

TGW is building a new and highly automated intralogistics system in the German town of Weilbach for ID Logistics, as part of the company’s existing distribution system.

Founded in 2001, ID Logistics is a French third-party logistics company serving many international customers. ID Logistics specializes, among other things, in food retailing, cosmetics, fashion, and DIY. With 275 branches worldwide and 19,000 employees, ID Logistics is one of the largest players in the industry. TGW is building a new and highly automated intralogistics system in the German town of Weilbach for ID Logistics, as part of the company’s existing distribution system.

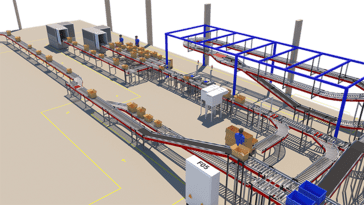

Going live is scheduled for summer of 2019. The order volume is in the single-digit million euro range. TGW is implementing a highly flexible FlashPick® system with more than 20,000 storage locations. This smart solution for automated piece picking helps reduce turnaround times. It is suitable for small orders as well as large ones – thus making it an ideal fit for businesses with rapid changes in product ranges.

At the heart of the system are a 3-aisle Stingray shuttle warehouse as well as PickCenter Ones – TGW’s high-performance workstations, while KingDrive® conveyor technology, now replacing the old system, will provide fast and energy-efficient transport.

Up to 30,000 orders per day

With TGW's new system, ID Logistics can now pack and move up to 2,000 containers per hour to their individual picking sites. In total, up to 30,000 orders can be processed per day. Thus, ID Logistics can significantly increase its productivity and continue to systematize order processing. This is accompanied by increased levels of flexibility: As order structures change, new market requirements can be met in a timely fashion. Thanks to 1:1 picking stations, picking errors can be mostly avoided. In addition, the system avoids unnecessary movement, thereby improving workstation ergonomics.

Short implementation phase

Patrick Teissier, CSO at TGW South Europe, emphasizes: “With this project, the extremely short implementation phase is a particular challenge. TGW planned this system together with ID Logistics and tailored it precisely to requirements. This enables ID Logistics to meet the high expectations of their customers quickly and flexibly – anytime.”