Intralogistics for grocery

We take care of the in-between.

Trust is the key to success

Strengthen the bond with your customers. Work with us to create a unique shopping experience for your customers and cater flexibly for their individual habits and preferences. Our flexible solutions allow you to continuously expand your product range and offer your customers a wide array of high-quality, fresh products.

Discover how our solution can raise your company to a new level of customer satisfaction and strengthen your competitive position.

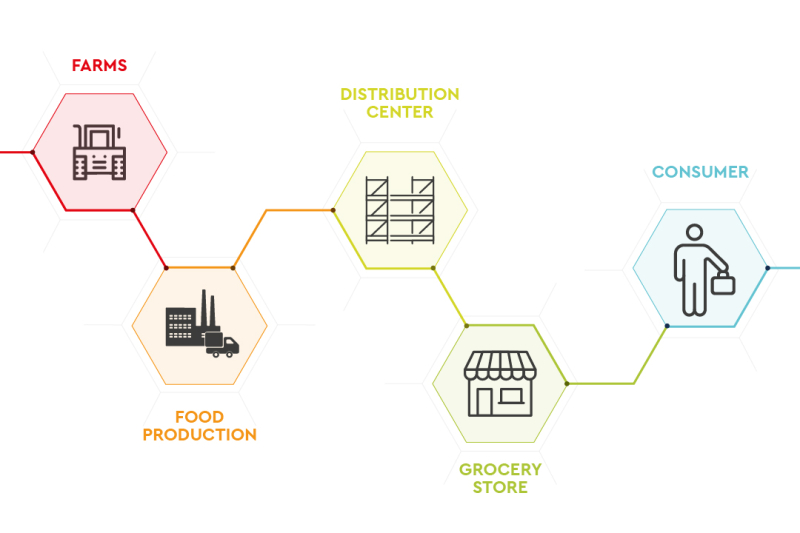

Efficient TGW intralogistics along the entire supply chain

With over half a century of experience, TGW Logistics is a reliable supplier of intralogistics solutions in the grocery industry. We offer flexible and scalable solutions for grocery retail and online shops, all from a single source.

Notable satisfied customers trust our expert knowledge as industry specialists and benefit from intralogistics solutions perfectly tailored to the respective requirements. We make long-term success possible in an industry with low margins. Our experts work with you to determine which intralogistics solution and what degree of automation are best suited for your company.

From X to Y – We take care of the in-between.

An increasing variety of products, more demanding customers, the rise in off-price stores, and the heightened focus on sustainable and intelligent packaging all present new challenges. We help you to find the ideal solution for your company.

From food production to e-commerce: TGW specialists develop tailored intralogistics solutions for brick-and-mortar retail, e-commerce, food production and food services. We have a great deal of specialist knowledge of intralogistics at our disposal, covering all temperature zones from dry and fresh goods to frozen food.

From the concept and planning of your project up to its implementation with hardware and software, we offer you tailored solutions from a single source. Furthermore, we are your reliable partner for everything from proactive care to immediate assistance if any problems should occur, from provision of spare parts to offers for modernisation and training.

TGW customers have full control

Our flexible systems allow you to maintain control over the interaction of different sales channels—including everything from goods receiving to storage to order picking and distribution. Thanks to their modular structure, our two standard solutions can ideally fulfil a wide variety of requirements.

As an experienced solution provider, TGW Logistics offers a comprehensive portfolio of mechatronic, robotic and software solutions. Our experts support your employees in optimising the use of existing spaces and installations. Thus, we work together to lay the foundation for your growth.

Systems & solutions

Every industry has its challenges - including, of course, the grocery production and retail sectors. We work with you to design the optimum solution for your requirements and implement it on time. Our systems & solutions for the food sector at a glance...

FullPick is a reliable and efficient system for creating mixed pallets and roll containers (mixed case palletising) for deliveries to customers and shops. Producers and retailers of food and food services can use it to automatically load both pallets and roll containers according to customer requirements.

Whether regional or central fulfilment centre: Our high-performance FlashPick goods-to-person system can be used in all temperature zones (ambient, chilled, fresh, frozen). We also take maintenance and servicing costs into account during the planning phase in order to maximise your business case by keeping the total cost of ownership as low as possible.

Satisfied customers

What was the initial situation and the intended goal, and what solution did we use to ensure that our customers are extremely satisfied with the result? A selection of current references...